Software Helps NASA Automate Robot Programming Process

A process being developed by the NASA Advanced Composites Project uses software to help automate the programming of collaborative robots for safe inspection of composite fuselage components alongside workers, providing more consistent results.

Share

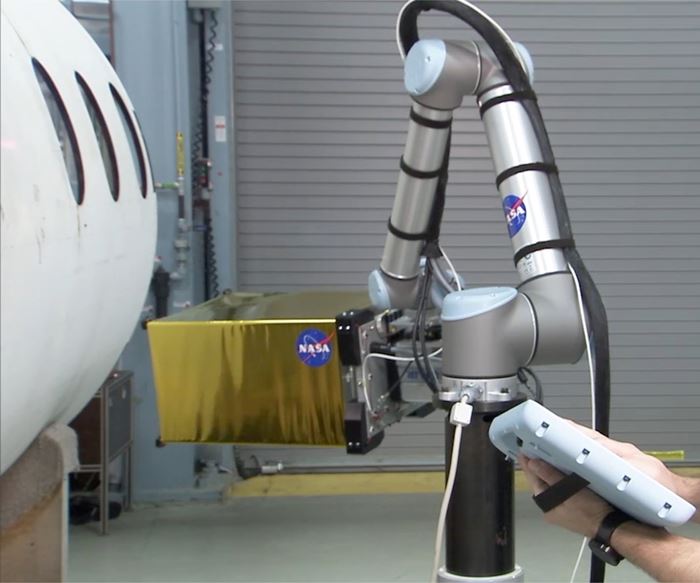

Automating processes with robotics can have numerous benefits, but robots require programming, a typically manual process that can be complex and lead to costly problems like collisions. The NASA Advanced Composites Project is working on a process that not only automates inspection of airplane fuselages using collaborative robots (cobots) from Universal Robots, it automates the programming of the cobots with software from robotic software simulation developer RoboDK. This system has the potential to save time and money while providing better, more consistent results than fully manual inspection processes.

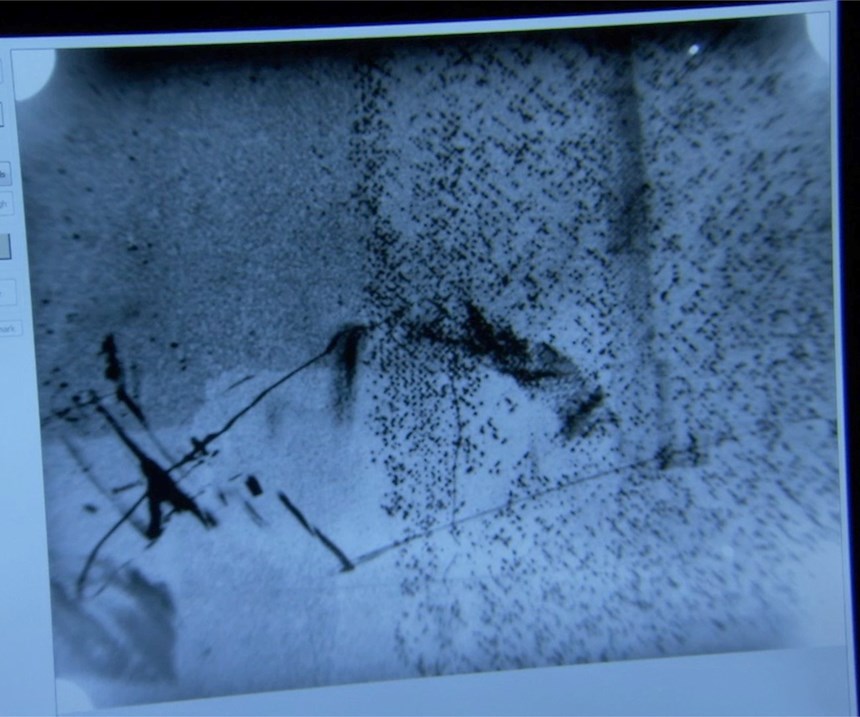

The NASA Advanced Composites Project works to improve methods, tools and protocols as well as reduce development and certification timelines for composite materials and structures as their applications increase. One of its goals is to speed the inspection of composite structures and improve measurement results by ensuring that the inspection procedure does not miss any areas of a structure. One inspection method is infrared thermography, which uses a precise flash of light to create a pulse of heat. As the material cools, researchers analyze how the heat flows through the part to reveal hidden defects and abnormal substructures without damaging the part. However, infrared inspection equipment is large and heavy, and it must be moved across the entire surface of the part inside and out to ensure a comprehensive inspection. Manual inspections of large composite products, such as airplane fuselages, require multiple operators for extended time periods, adding cost and complexity.

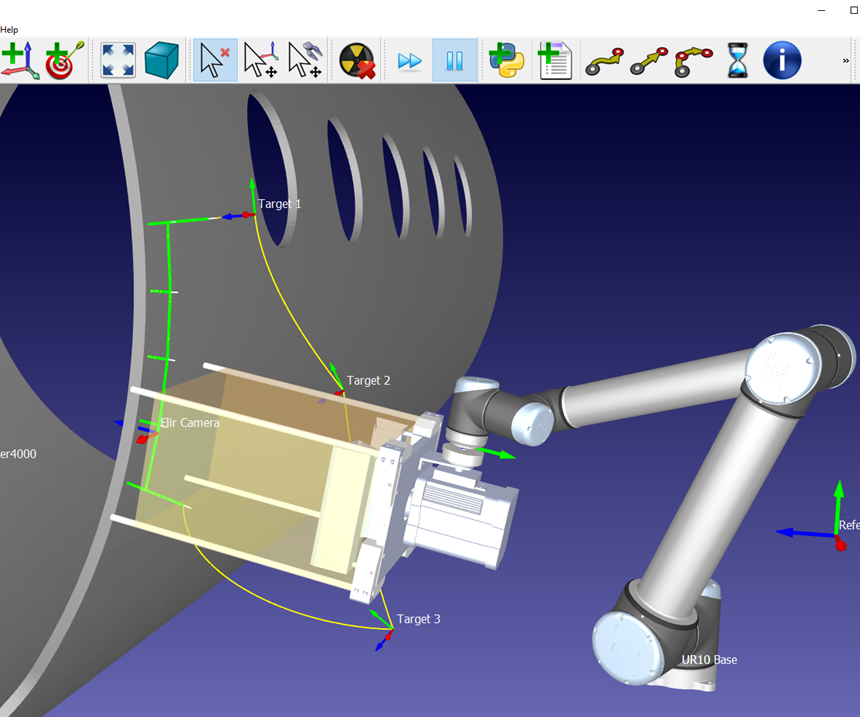

To automate this process, the NASA Langley Research Center is testing a method that uses software from RoboDK to automate the programming of inspection patterns for two UR10 cobots from Universal Robots. Researchers used the software to create a computer model of the part to be inspected, the inspection pattern and the movement of the inspection tool. The software has an application programming interface (API) that enables users to program robots using universal programming languages, such as Python, C#, C++, Matlab and Visual Basic.

Once the inspection process is calibrated and the cobots are properly located with respect to the part, the cobots can follow a pre-programmed path to move the inspection equipment into precise locations around the fuselage and hold the equipment in place as the operator retrieves the data.

The software can be customized with algorithms to automate some tasks, such as projecting an inspection pattern onto a surface to simulate and generate the inspection program. The algorithms can be fully or partially automated, meaning they generate the tool path according to certain parameters that can be modified by the operator or robot programmer. With custom, fully automated algorithms, robots can be programmed in just a few seconds, says RoboDK CEO Albert Nubiola. The NASA Advanced Composites Project uses an algorithm that creates a tool path for the robot to follow on the surface of the fuselage, avoiding windows and holes.

The software’s API also enables users to create programs offline and simulate them before downloading them to the robot. “Offline programming of the robot is very useful when you need to do the planning work prior to moving the robotic system to a hangar or other location,” says NASA Analytical Mechanics Associate Joshua Brown. He adds that the simulation function is also helpful, as it can be used to check for problems like axis limits and collisions, which are a potential problem when using multiple cobots. “It’s been fairly simple to bring multiple robots into a station and get them working together virtually before having the real metal flying around,” Mr. Brown says. Once the program is created and simulated, it can be downloaded to the robot, so inspection can begin without additional setup.

The system is in the early stages of development, and Mr. Brown says the goal is to get the framework for the inspection system in place and work out some of the details. Currently, the cobots must be moved manually to different areas around the fuselage and then recalibrated before performing a scan based on the surface in that area. The next phase of development involves mounting the cobots on a linear stage that will extend the reach of the system to roughly 3 meters. That linear stage also could be mounted on another linear stage or pair of linear stages to extend the system’s reach in another axis or plane.

This system has the potential to save time and money, as it enables a single operator to oversee the inspection process. Programming and simulation ensure efficiency, because the robots move on the most practical and comprehensive paths around the aircraft. Simulation can also prevent potentially costly problems. In addition, the cobots have a safety system that monitors when to switch into a reduced-safety mode and stops operation when it comes into contact with a person. This enables people to work closely alongside them, so other inspection or manufacturing processes can take place during infrared inspection. This method also has the potential to improve the quality of inspection results, as it can be used to ensure that the entire part is inspected.

However, Mr. Brown says that at this point, the reliability this system can provide is more valuable than possible time and money savings. “Using robots means consistency and the ability to go back and do an inspection in exactly the same way in exactly the same spot with no human error,” he says. “Human operators just can’t move like a robot can and that’s why we’re investing in this.”

Related Content

Marathon Precision’s Engineering Playground: One Shop’s Secret to Sustaining High Tech, Low-Volume and High Morale

Half an airplane on the wall, a ten-foot metal dragon, and a full-blown recording studio might not scream “manufacturing efficiency,” yet Marathon Precision proves otherwise. Here’s how forging, complex CNC operations and staff-driven creative projects combine to fuel the shop’s productivity and profitability.

Read More4 Ways to Establish Machine Accuracy

Understanding all the things that contribute to a machine’s full potential accuracy will inform what to prioritize when fine-tuning the machine.

Read MoreA 100-Year-Old Measurement Tool That is Still Used Today

The reed mechanism was a breakthrough in high-precision measurement and is still used today for sub-micron or even nanometer resolution applications.

Read MoreUnderstanding Structured Light Scanning Measurements

Structured light scanning is used to create a digital twin of a manufactured part, but we must understand the measurement reproducibility to best use the data.

Read More