The Internet of Things

The push to make manufacturing a fully integrated Internet-of-Things world is gaining momentum

Share

The Internet of Things is a useful catchword that generally refers to the concept that many things can be equipped with intelligent sensing devices that allow them to be monitored, automated or controlled remotely, using the Internet as the communication network. The appeal of this concept is often presented along the lines of this scenario: A Wi-Fi enabled device on your front door will operate the lock to grant entry to pre-authorized family members whose presence is detected as they approach, or to friends dropping by unexpectedly, who you will admit once notified that they are at the door. You may also be notified that the six soft drinks your guests consumed while waiting for your return have triggered a replenishment order that will be added to the weekly grocery order.

Many aspects of current technology for the factory and machine shop already incorporate provisions for remote monitoring, maintenance and control. These advances are already making manufacturing more flexible, productive and convenient. Quality and profitability also get a boost. That said, implementations of this technology are still rather rare, incomplete and somewhat experimental. However, the push to make manufacturing a fully integrated Internet-of-Things world is gaining momentum. For example, Germany’s “Industry 4.0” is a national initiative with this explicit goal. Industry 4.0 is seen as the fourth industrial revolution, one that, in theory, will thoroughly transform manufacturing, based on what proponents there have termed Cyber Physical Systems. The implications are global.

We’ve already seen glimpses of the new shape manufacturing may take. It will be decentralized, highly localized, but broadly distributed. Every machine tool will have the capability to function as an on-demand “mini job shop” serving as a node on a unified, coordinated and integrated manufacturing system. (No doubt some manufacturing assets will be based in our homes.) An online agency is likely to arise to facilitate and regulate the transactions across large branches of this network much the way Amazon, eBay and Google do today in their respective spheres.

Perfecting the sensors and data processing capability to support this revolution will take years.The development and growing implementation of MTConnect, an open, royalty-free set of communications standards intended to foster greater interoperability between manufacturing equipment, is a great headstart. Here’s a critical point—this emerging approach to manufacturing will be consumer-driven. That is, the development will lead to a system in which the consumer or end user will initiate the production of each Thing in the Internet of Things.

Let’s say you decide to upgrade the above-mentioned entry system on your front door. You set the basic specs, or help design this new system. At your signal, a cascade of commands flows to the most appropriate manufacturing assets to machine or mold all of the requisite components, collect them for assembly and ship the finished unit. Hours later, you’ve installed the new device. Cars, appliances and electronic gadgets of all sorts will follow a similar path.

Is this transformation achievable? Inevitable? Advisable? Will it be secure, humane and sustainable? The answers lie within the human spirit.

Related Content

2 Secondary Coordinate Systems You Should Know

Coordinate systems tell a CNC machine where to position the cutting tool during the program’s execution for any purpose that requires the cutting tool to move.

Read MoreThe Smarter Way to Take Full Control of Your CNC Machine Shop

Designed to bridge the gap between CAM programmers and shop floor operators, SolidShop provides a seamless, real-time solution for managing G-code, tracking production and eliminating costly mistakes.

Read MoreShop Reclaims 10,000 Square Feet with Inventory Management System

Intech Athens’ inventory management system, which includes vertical lift modules from Kardex Remstar and tool management software from ZOLLER, has saved the company time, space and money.

Read More10 Robotic Solutions You Can Find at IMTS 2026

Discover how today’s robots and cobots are making it easier than ever to automate tasks, free up skilled workers, and run machines unattended – even in small and midsized shops.

Read MoreRead Next

MTConnect Is For Real

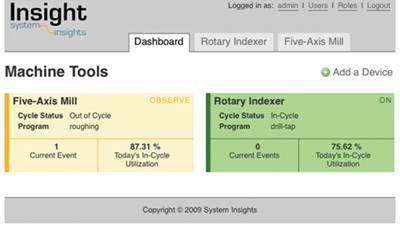

Introduced at IMTS 2008, this communications protocol for CNC machines and other manufacturing equipment is already helping shops and plants implement effective machine monitoring systems. Although these "early adopters" are motivated by the long-term promise of enterprise-wide efficiency gains, their experience with pilot projects shows that benefits derived in the short term are substantial and worthwhile.

Read More

.png;maxWidth=300;quality=90)