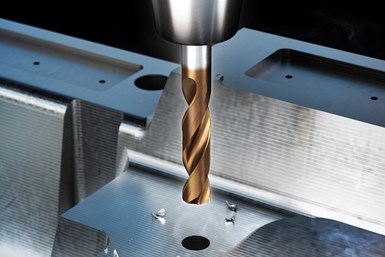

YG-1's Dream Drills Pro Optimized for Steel, Cast Iron

The Dream Drills Pro tools are made with micrograin carbide for core strength and longer tool life, and feature the company’s wave-shaped cutting edge to reduce cutting forces.

Share

YG-1 has beefed up its Dream Drills line-up with the new Dream Drills Pro line, which is optimized for machining in steel and cast iron. According to the company, the main advantages of these tools are increased cutting speeds and tool life.

The Dream Drills Pro tools are made with micrograin carbide for core strength and longer tool life. They also feature the company’s wave-shaped cutting edge to reduce cutting forces, and a wide-flute design optimized for faster, reliable chip evacuation. A self-centering 140-degree point angle reduces torque and extends tool life.

YG-1’s silicon-based, nano-layered Z-Coating technology gives cutting edges high hardness and heat resistance to improve tool life, while producing good surface finishes and a high number of parts per tool. The tools come in drilling depths of 3×D to 5×D.

Related Content

-

Choosing the Right Drill Type

Specifying the right option for your application can save time and tools.

-

Measuring Torque, Thrust Force for Smart Drilling Operations

To monitor drilling operations for smart manufacturing solutions, torque and thrust force can be measured.

-

Inside the Process of Cutting Tool Recycling

Global Tungsten & Powders, part of the Ceratizit Group, sheds light on the processing steps that convert a shop’s used inserts into new tools and other applications.