High-Speed Machining

Fast Machining With Fewer Tools

Machining centers capable of precise motion at high feed rates can reduce the number of tools it takes to complete a part.

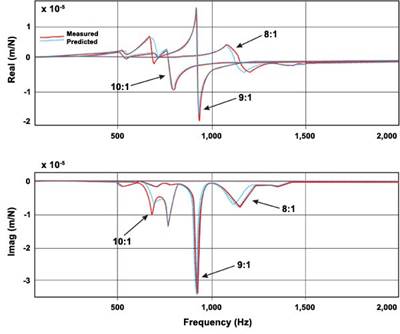

Read MoreUnderstanding Surface Location Error

Change your speed by a few hundred rpm and the tool’s effective cutting radius may change.

Read MoreSweet, Sweet Spot

For this aerospace job shop, harmonizing key aspects of each high speed machining process creates a "sweet spot" where productivity jumps. Harmonizing other key aspects of shop operations also creates a "sweet spot" that helps the company capitalize on this jump in machining productivity.

Read MoreMicro Milling At 1/2 Million RPM

Researchers aim to develop a spindle that accounts for the differences between macro and micro machining.

Read MoreThinking Outside The Cut

A Silicon Valley manufacturer's survival strategy involves closer relationships with customers, and high speed machining is crucial to this. The shop pays particular attention to the process factors that affect high speed machining before the cut takes place.

Read MoreAutomation's Extended Reach

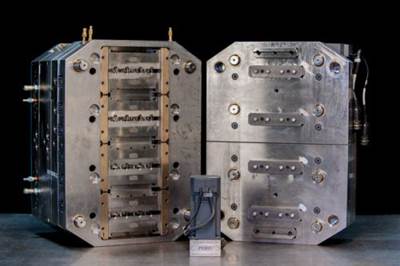

The experience of a Windsor mold shop offers an object lesson in machine shop automation. In an interconnected process, automating one aspect of the process offered benefits beyond what the initial planning had led the shop to expect.

Read MoreSix Advantages Of Horizontal High Speed Machining

Large monolithic aircraft parts may be machined more productively one at a time instead of three at once.

Read MoreThe Overhang Effect

The length by which the tool extends from the toolholder is a variable that can be used to 'tune' the machining process. Contrary to what you may expect, increasing the tool's L:D ratio may reduce chatter and result in more productive milling.

Read MoreHigh Speed Machining, Italian Style

One of the highlights of BI-MU, Italy's recent biennial machine tool show, was the number of innovative machine tools (and related technology) focusing on high speed machining.

Read MoreHigh Speed Electric Spindle Rigidity Helps Company Meet Quality Challenges

High spindle speed is a necessity for this engraving company, but the rigidity of the spindle is another major factor in achieving quality engraved numbers, letters, logos or other characters.

Read More

.png;maxWidth=300;quality=90)