-

-

SPONSORED

-

SPONSORED

-

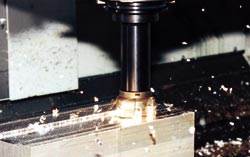

High-Speed Machining

Going Beyond Three-Axis Milling

In its quest for greater moldmaking efficiency, this shop added fourth- and fifth-axis positioning mills and is about to buy its first continuous five-axis mill.

Read MoreThe Fluid Transition

A watershed moment in spindle evolution? For the latest generation of high speed spindles used in milling, spindle makers look beyond traditional bearings.

Read MoreHigh Speed Milling: A Competitive Necessity

The use of high speed milling in moldmaking shops is no longer viewed as merely providing a firm with a competitive advantage. It is a disruptive technology that is becoming a competitive necessity.

Read MoreMaximum Aluminum: Optimizing Metal Removal Rate in Aluminum with a High Speed Spindle

Speed changes the rules. To maximize metal removal rate with a high speed spindle, follow some fundamental tooling considerations and mill at just the right rpm.

Read MoreHigh Speed Spindles Provide Focus For Single-Machine Piston Production

Focus:HOPE is a non-profit Detroit organization that teaches manufacturing skills from basic machining through CNC operations and also offers associate's and bachelor's degrees through the organization's Center for Advanced Technologies.

Read MoreBoosting Machine Output While Using Fewer Toolholders

Toolholder distortion can impede machining operations, especially if the toolholder walls collapse during high speed operation. All sorts of problems can result, from cutting tool breakage and loss of the machined parts to costly damage of the machine spindle and drawbar.

Read MoreBringing Toolholders Up To Speed

For the Wichita, Kansas, division of aircraft manufacturer Boeing, one aspect of effective high speed machining is finding the right balance. The division machines aluminum at speeds ranging from 15,000 to 40,000 rpm. To cut at these high speeds as effectively as possible, Boeing uses both pre-balanced and balanceable toolholders.

Read MoreWhat's Possible At 10,000 RPM

High-value work doesn’t have to demand a high-cost machine tool.

Read MoreFor High Speed And High Productivity, Keep Cool And Stay Calm

Machine tool builders have developed methods to cool off spindles and damp machine vibration for stable machining at higher spindle speeds and faster feed rates.

Read MoreFind The Right Speed For Chatter-Free Milling

It used to be that a little chatter was easy to forgive. Not anymore. In shops aiming to minimize hand finishing, machined surfaces have to be smooth. And in high speed machining applications, chatter itself can set the speed limit.

Read More

.png;maxWidth=300;quality=90)