Reducing the Weight of a Robot Actuator

A metal additive manufacturing process reduced the weight of a hydraulic actuator, leading to a better performing component.

Share

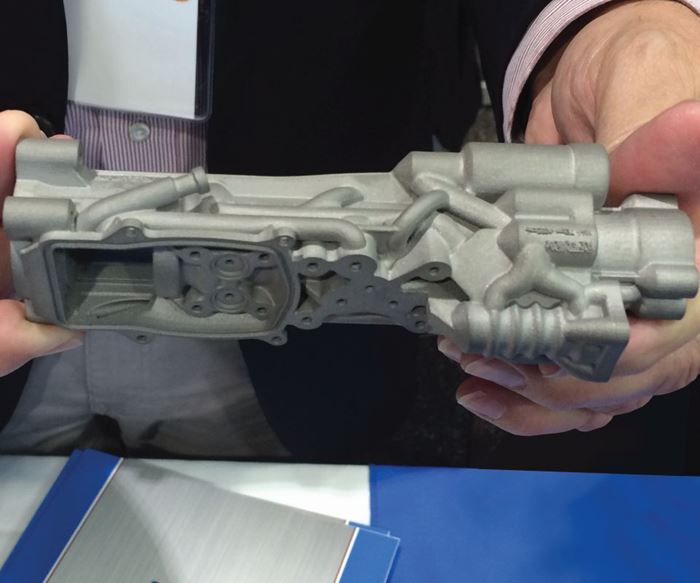

This highly integrated electronic actuator for a hydraulic quadruped robot needed to meet design requirements while achieving a 50 percent weight reduction, compared to a traditionally manufactured actuator body.

A powder-bed metal additive manufacturing process called selective laser melting (SLM) allowed it to be made as one piece. The part was grown layer by layer in Ti6Al4V (titanium alloy) on a Renishaw AM250 industrial 3D printer at the Moog Additive Manufacturing Center (now part of Linear AMS).

The new actuator’s one-piece construction reduces manufacturing operations, improves performance through design features such as curved flow tubes that eliminate right-angle drilling, and reduces weight as a result of downsizing. Traditional manufacturing would have entailed combining the cast and fabricated pieces with brazing and welding operations.

This particular actuator is used on each leg of a quadruped robot developed at the Italian Institute of Technology in Genoa, where it was designed initially for military applications. However, a similar actuator concept can also be used in many other applications, for example: heavy equipment, such as tractors and large earth-moving equipment, for weight and size reduction; military and commercial aircraft, to control velocity and engine speed by adjusting levers and flaps; and injection-molding applications for exact precision control.

Related Content

-

OEMs Showcase Hybrid Manufacturing Applications

Mazak and Mastercam worked together to demonstrate the viability of hybrid additive/subtractive machining techniques at a recent event held in Florence, Kentucky.

-

Push-Button DED System Aims for Machine Shop Workflow in Metal Additive Manufacturing

Meltio M600 metal 3D printer employs probing, quick-change workholding and wire material stock to permit production in coordination with CNC machines.

-

Video: Apply Metal and Machine It With Hermle’s Metal Powder Application (MPA) Process

The Metal Powder Application (MPA) process uses cold spray to apply metal to an existing workpiece. Because the material deforms rather than melts, MPA opens new possibilities for functional grading and other multimaterial applications.