The Value of a "Pathfinder Part" for Additive Manufacturing

Implementing additive manufacturing means starting somewhere. Seeking out the right pathfinder part can illustrate valuable lessons about the advantages of this technology.

Share

“If you think about the legacy platforms that our Department of Defense has across the board, when something comes out of service there’s a cost to that. There’s a cost to the taxpayer; there’s a cost to the warfighter,” says Brian Morrison. “There are so many different applications out there where additive can solve a problem to get these legacy platforms back to work.”

Morrison is director of additive manufacturing (AM) for Allegheny Technologies Inc. (ATI), a position where he has led the company’s development of titanium and nickel alloys for metal 3D printing. In this role he also works closely with Rich Merlino, senior director of AM and the leader of ATI’s parts production business. Both areas of the business inform each other; the production team can call on material expertise to select powders or create new alloys when needed, while the materials team gets insight into real customer challenges and applications from the production side.

Together Morrison and Merlino have seen customers make the leap to additive, and what makes an application a good fit for AM. Ideally, they say, a company’s first step with additive manufacturing for production should be a pathfinder part — that is, a component similar to other parts in the company’s inventory such that pursuing 3D printing as a production method helps pave the way for future parts.

What makes a good pathfinder part? There are several contributing factors to take into account:

- The part solves a problem. ATI has seen that specific needs are always the best use cases for additive manufacturing. Without an urgent problem to solve, companies can spend years researching and investigating 3D printing without making any real move.

- The problem can only be solved with 3D printing. “When a customer says, ‘I have a component and it’s made this way today and it’s going fine but I want to explore additive,’ that’s not going to go anywhere,” Merlino says. But if that customer has already tried and discarded machining, casting, fabricating and any other option, additive manufacturing tends to succeed.

- The design can be flexible to the needs of both AM and finish machining. Depending on the process used, additive manufacturing may require certain changes or accommodations in the design. Material might need to be removed for instance to save time in printing, or maybe added to help with locating the part for finish machining. Some design flexibility is generally necessary to create a successful pathfinder part.

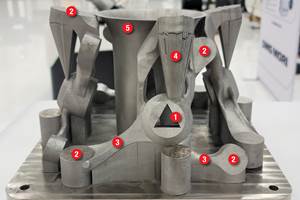

The as-printed oil collector. ATI had free rein in the design of this upgrade part, but concessions were made for the EBM process and to support finish machining. More.

One last but significant note: The pathfinder part need not be a component that already exists. Brand-new parts often represent the greatest opportunity because of their complete design freedom. With no incumbent processes or tooling to contend with, additive manufacturing is free to deliver the best possible solution.

This was the case with one recent example, an oil collector that ATI created with electron beam melting (EBM). The piece is an upgrade for a fleet of helicopters that were suffering from oil leakage. Though the part was a new one, it proved to be a good case for metal AM and helped the customer learn how to include additive in the design philosophy going forward. Learn much more about this component in this article.

8 Cool Parts from RAPID + TCT 2021: The Cool Parts Show #32

Prefer a visual? The ATI oil collector was one of the items on display at this year’s RAPID + TCT, the largest trade show in North America devoted to 3D printing technology. The part made it into this special episode of The Cool Parts Show highlighting some of the most interesting 3D printed things we found on the show floor.

Related Content

Designing a 3D Printed Part with Machining in Mind

Designing extra stock and mounting features into a 3D printed part can aid in machining processes downstream.

Read MoreVideo: Apply Metal and Machine It With Hermle’s Metal Powder Application (MPA) Process

The Metal Powder Application (MPA) process uses cold spray to apply metal to an existing workpiece. Because the material deforms rather than melts, MPA opens new possibilities for functional grading and other multimaterial applications.

Read MoreMachine Tool Drawbar Made With Additive Manufacturing Saves DMG MORI 90% Lead Time and 67% CO2 Emission

A new production process for the multimetal drawbar replaces an outsourced plating step with directed energy deposition, performing this DED along with roughing, finishing and grinding on a single machine.

Read MoreAdditive/Subtractive Hybrid CNC Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)