Hennig, Inc.

.1727710676666.png;maxWidth=200)

9900 N Alpine Road

Machesney Park, IL 61115 US

1 888-436-6446 | 815-636-9900

info@hennig.ame.com

hennigworldwide.com

About Hennig, Inc.

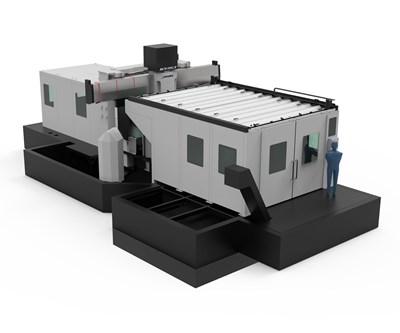

Hennig helps create and maintain a safe and efficient workplace for manufacturers, safety facilities, stand-by power systems, and maintenance facilities around the globe. Since 1950, Hennig has been defining excellence while supporting the global needs of machine tool customers.

IS THIS YOUR COMPANY?

Video Gallery

Opportunities & Growth | Careers at Hennig

One hour west of Chicago in Rockford, Illinois, there's a global manufacturing company with a community-driven culture: Hennig.

Cover Your Assets | Protect Your Success

Manufacturing is the lifeblood of industry, productivity, and even GDPs. If your equipment and your people need to be protected, ...

800,000+ sqft of Power Protection | Hennig Power Protection

You may have just found the generator enclosure partner you've been looking for. At Hennig, our Power Protection team ...

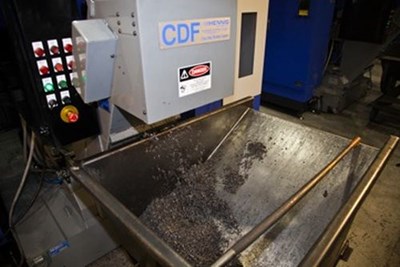

Innovations in Chip Management: Hennig's VariFlow High Pressure Coolant System

Join Tony Gunn of MTD CNC as he interviews Hennig's Camoren Schley at Westec 2023 to discuss the newly released VariFlow ...