micromachining

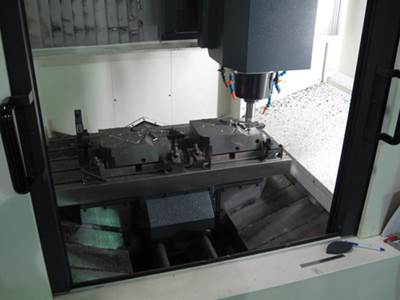

Micromachining Powder Metal on a VMC

By refining its micromachining process for powder metal tool steels, this shop has reduced production costs, lead times and secondary bench work for complex tooling components.

Read MoreHow Do You Equip a Startup Micromachining Shop?

A response to a reader’s question includes a checklist for launching a small shop focused on micromachining.

Read MoreControlling Burr Formation within Small Intersecting Holes

A reader struggles with burrs between intersecting holes 1 mm and less in diameter. MMS Online’s micromachining expert offers advice.

Read MoreWhat's the Best Process for Machining a Precise Hole in Aluminum?

This small hole is actually large enough that any of three different processes might be used.

Read MoreThe Importance of Float During Micro Reaming

Micro reamers require a floating holder to compensate for any machine positioning inaccuracies.

Read MoreNew Waterjet Technology Offers Micromachining Alternative

Micro Waterjet LLC offers a machine that overcomes the lack of positioning accuracy and limited cutting stream control that have historically barred waterjet from work at the micro scale.

Read MoreHard Milling Isn’t Just High Speed Machining

Milling complex forms in hardened tool steel involves more than just fast, light cuts, says this maker of medical-related injection molds. Here are some of the ingredients of an effective hard milling process.

WatchWhen to Mill Keeps Changing

Technology improvements steadily expand the range of tool and die parts that justify high speed machining.

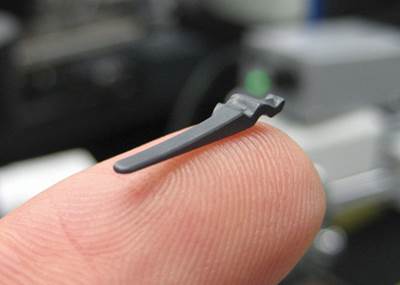

Read MoreIt Takes Firm Resolution To Master The Micro

This shop’s experience of successfully machining a micro aneurysm clip in silicon nitride ceramic points out the need to have CAD, CAM and CNC capability at high resolution—plus the commitment to pull it all together.

Read MoreDoes Small-Hole Drilling Demand a Fast Spindle?

A reader with a 10,000-rpm drill press can drill a 0.019-inch hole in stainless, as long as all the contributors to runout are controlled.

Read More

.png;maxWidth=300;quality=90)