Turning Tools

Tungaloy Supplies TungCut Grooving Tool with Coolant Supply

Tungaloy has expanded its TungCut series of grooving tools to include the CGP32-CHP parting blade.

Read MoreTungaloy Expands TungThread Line with 11ER Threading Inserts

Tungaloy has expanded its TungThread line of indexable threading tools to include 11ER external threading inserts as well as 8 × 8- and 10 × 10-mm square-shank holders

Read MoreTungaloy's TungBoreMini Combines Drilling and ID, OD Turning

The TungBoreMini, a multifunctional drilling and turning tool from Tungaloy, is designed to combine the capabilities of drilling and OD and ID turning tools.

Read MoreDormer Pramet's GL Tool Designed for Long-Grooving Applications

Dormer Pramet has added a new set of tooling to its parting-off and grooving assortment.

Read MoreWalter USA Adds PCD Inserts to Its Cut GX Grooving Series

Walter USA has added polycristalline diamond (PCD) grooving inserts to its Walter Cut GX grooving system.

Read MoreHow AM Is Advancing into Cutting Tools: Photos from EMO

The design freedom of additive manufacturing delivers increased performance to cutting tools. At the world’s leading exposition for machine tools, I saw various examples of this.

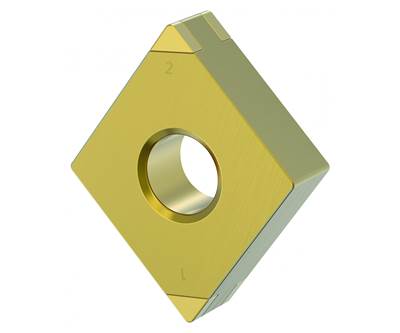

Read MorePCBN Inserts from Kennametal Make Hard Turning More Cost-Effective

Kennametal’s KBH10B and KBH20B grades, designed for hard turning, are available in double-sided inserts for materials as hard as 65 HRC.

Read MoreHorn's Supermini Gets an Insert Geometry for Drilling, Boring, Face Turning and Skimming

Designed for the Supermini tool system, Horn’s HP geometry is suitable for drilling, boring, face turning and skimming.

Read MoreInterrupted Turning Operation Cuts Cost With 10-Sided Insert

Using a robust 10-sided insert from Tungaloy, this oil-industry remanufacturer was able to reduce the number of inserts used in interrupted turning operations.

Read MoreModulated CNC Turning: How a Reversal in the Tool Path Can Deliver Greater Cutting Speed

UNCC researchers introduce modulation into the tool path. Chip breaking was the goal, but higher metal removal rate is an intriguing secondary effect.

Watch