-

-

SPONSORED

-

SPONSORED

-

Micromachining

MC Machinery Technology Summit Showcases Manufacturing Innovations

MC Machinery Systems Inc. hosts the 2025 Technology Summit in Elk Grove Village, Illinois, featuring EDM, milling, automation and workforce strategies.

Chris Pasion

Managing Editor, Modern Machine Shop | Production Machining

Watchmaking: A Machinist’s View

Old-world craftsmanship combines with precision machining on a vertical machining center and Swiss-type lathe to produce some of the only U.S.-made mechanical wristwatch movements.

Read MoreFive-Axis and Clever Controls Support Medical Manufacturing

Kern’s Micro Vario and Heidenhain’s TNC 640 control give M5 the precision and accuracy it needs to successfully micromachine medical parts.

Read MoreMicro 3D Printing Solves Big Problem for Tiny Parts

3D printing is a well-known tool for prototyping, but only recently has the technology reached the point that it can handle the tiny features and tight tolerances of micro parts.

Read MoreTransitioning to CNC Swiss-Type Machining? Here’s How One Shop Did It.

The introduction of CNC Swiss-type machines at Deking Screw Products brought a new and highly efficient production method to the business. But it also required learning the distinct differences inherent with Swiss-type machining, and a mindset change for the company’s leaders.

Read MoreHolding Submicron Part Tolerances

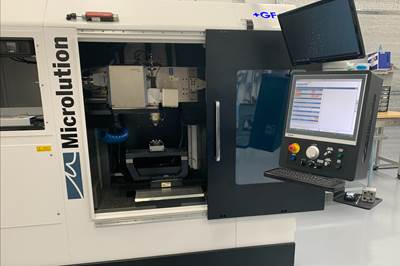

Sunlight-Tech Inc. has used GF Machining Solutions’ Microlution laser micromachining and micro-milling centers to produce parts with tolerances tighter than 1 micron.

Read MoreFour New High-Performance Milling Techniques for 3D Machining

With many 3D milling applications demanding both shorter cycle times and smoother surface finishes, it’s time to review how you go about programming and machining parts. These four strategies will let you rough dramatically faster and achieve astonishingly fine surface finishes.

Read MoreA History of Precision: The Invention and Evolution of Swiss-Style Machining

In the late 1800s, a new technology — Swiss-type machines — emerged to serve Switzerland’s growing watchmaking industry. Today, Swiss-machined parts are ubiquitous, and there’s a good reason for that: No other machining technology can produce tiny, complex components more efficiently or at higher quality.

5 Tips for Making the Switch to Micromachining

Working at the micro-level requires changing the way you approach machining parts, and these tips can help you avoid pitfalls.

Read MoreBridging a Skills Gap with Micromachining

As experienced model makers aged out of the jewelry industry, R&D Manufacturing found a faster alternative to hand crafting in Datron’s Neo micro milling machine. It all came down to rpm.

Read MoreMicromachining End Mill Handles Materials as Hard as 65 Rc

Expanding the Jabro range of solid carbide end mills, Seco’s JM100 Mini is designed for shops struggling to machine micro-size workpieces with adequate surface finish, accuracy and precision.

Read MoreHigh-End Watchmaker Eliminates Offshoring with Five-Axis Machining Center

Instead of shipping small components from overseas, a watchmaker was able to accommodate increased demand by purchasing a used five-axis machining center.

Read MoreJet Coolant Nut Directs Fluid to Cutting Edge in Micromachining

Big Kaiser’s Mega micro coolant nut is said to provide precise coolant supply to micro cutting tools applications at high speeds when using the Mega micro chuck 6S.

Read More4 Takeaways for Shops New to Micromachining

By taking the plunge into micromachining, one Minnesota micro molding and machining shop now specializes in the design and production of parts 0.015 inch and smaller. Here is that story and the lessons learned in the process.

Read MoreWhere Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

Lori Beckman

Executive Editor, Products Finishing

Manufacturer of Precision Micro Parts to Debut in North America

Tavadec S.A. will formally launch at IMTS 2018 through an exclusive partnership with IndustryControlling LLC.

Read MoreMoving Past Micro-EDM Boundaries

To push past the limits of conventional EDM equipment, this German injection molding company adopted atypical micro-EDM “milling” technology to machine small molds for tiny, critical, injection-molded parts.

Read MoreWhat Should You Consider When Turning Micro Parts on a Lathe?

Various factors, including the machine, cutting tools and operator, must be taken into consideration to turn very small parts.

Read MoreHorn Continues Growth Path

The company highlighted its facility expansions and new cutting tool technologies during a recent open house at its global headquarters in Tübingen, Germany.

Read MoreGF Machining Solutions Hires Director of Business Development

Karl Kleppek will oversee sales, business development and marketing.

Read MoreDrilling “Invisible” Holes

UV laser micromachining makes it possible to drill holes that are not visible to the human eye—until they are meant to be seen, that is.

Read More3 Tips to Accelerate Production on Swiss Lathes with Micro Tools

Low RPM lathes can cause tool breakage and prevent you from achieving proper SFM, but live tooling can provide an economical solution for these problems that can accelerate production.

Backing Tech with Technique

Whether in machining or any other pursuit, knowledge and the right touch are critical to taking full advantage of technology and equipment.

Read MoreMachine “Power Users” Push Limits of Precision

For this shop, moving into micron-tolerance work required not just a new machining center, but also a willingness to understand technical features and techniques that never come into play for many programmers and operators.

Read MoreMachining Micron-Tolerance Micro-Parts Teaches Lasting Lessons

Different tools and machining strategies have driven this shop to seek new efficiencies beyond its most demanding work and most capable machining center.

Read MoreAdvancing to Micromachining on a CNC Swiss Lathe

By moving up from a standard lathe to a Swiss-type machine, this company can now bid on making small, complex parts it wasn’t able to in the past, while also slashing cycle times on legacy parts.

Read MoreGF Machining Solutions to Acquire Micromachining Specialist Microlution

The move is part of GF’s expansion strategy to target industries such as aerospace and medical.

Read MoreFundamentals Can Go a Long Way

For this shop, machining small parts from plastic is largely about applying the basics on a smaller scale.

Read More.png;maxWidth=728;quality=90)

.png;maxWidth=300;quality=90)