-

-

SPONSORED

-

SPONSORED

-

Basics

Tips for Monitoring Spindle Loads and Cutting Stability

When it comes to utilizing the spindle’s power, there is a lot of headroom at the upper limits, provided it’s in short bursts. Be mindful of your time at these loads so you don’t stall out.

Read More4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

Read MoreHave you Shown Your Value to Customers?

Showing your shop’s value is about more than simply offering the best price.

Read More3D Printing for Job Shops: Part of Elevate Job Shops Series at IMTS

A half-day workshop at the International Manufacturing Technology Show helps job shops explore the many potential ways 3D printing technologies support and enhance machining.

Read More4 Rules for Running a Successful Machine Shop

Take time to optimize your shop’s structure to effectively meet demand while causing the least amount of stress in the shop.

Read More3 Considerations for Revising Design for Manufacturing Efforts

When revising part designs, investigate the 3D CAD, the 2D drawing and the part’s functional requirements to determine which details should be tightened up.

Read MoreObscure CNC Features That Can Help (or Hurt) You

You cannot begin to take advantage of an available feature if you do not know it exists. Conversely, you will not know how to avoid CNC features that may be detrimental to your process.

Read More4 Tips for Staying Profitable in the Face of Change

After more than 40 years in business, this shop has learned how to adapt to stay profitable.

Read More6 Variations That Kill Productivity

The act of qualifying CNC programs is largely related to eliminating variations, which can be a daunting task when you consider how many things can change from one time a job is run to the next.

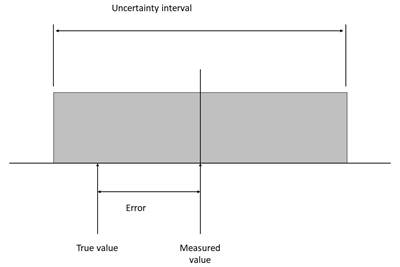

Read MoreHow to Evaluate Measurement Uncertainty

Manufacturing and measurement are closely coupled. An important consideration for the use of measurement results is the associated measurement uncertainty. This article describes common metrology terms and provides an example uncertainty analysis.

Read More

.png;maxWidth=300;quality=90)