-

-

SPONSORED

-

SPONSORED

-

Basics

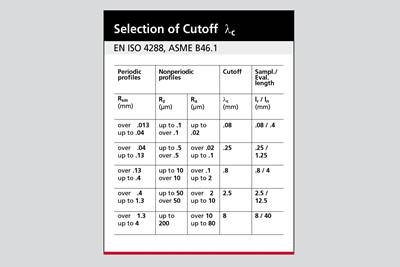

How to Choose the Right Cut Off When Measuring Roughness

Measurement results for surface finishing parameters can vary depending on the filter parameter (Lc), also known as the cutoff.

Read MoreBuying a Lathe: The Basics

Lathes represent some of the oldest machining technology, but it’s still helpful to remember the basics when considering the purchase of a new turning machine.

Read MoreUnderstanding G27, G28, G29 and G30

Take a closer look at these reference position commands.

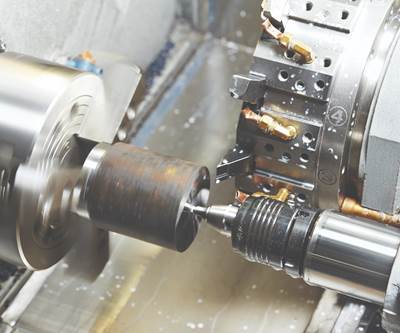

Read MoreThreading On A Lathe

The right choices in tooling and technique can optimize the thread turning process.

Read MoreUnderstanding Swiss-Type Machining

Once seen as a specialty machine tool, the CNC Swiss-type is increasingly being used in shops that are full of more conventional CNC machines. For the newcomer to Swiss-type machining, here is what the learning curve is like.

Read MoreUnderstanding CNC Machine Accuracy and Repeatability

Properly evaluating machine tool capability requires understanding how the both user and the builder can influence precision.

Read MoreUnderstanding Errors In Hand-Held Measuring Instruments

Different instruments (and different operators) are prone to different errors.

Read MoreWhen to Use Custom Macros With a CAM System

Custom macros can offer benefits even when using a CAM system to prepare programs – but must be implemented with the right considerations.

Read MoreHow To Calibrate Your Calipers

If you’re interested in calibrating your own digital, dial or Vernier calipers, here are some steps to take to make sure it goes off without a hitch.

Read MoreHow to Grow the Business with Real-Time Job Status Data

ERP systems that focus on making data more accessible can improve communication within a shop, reducing wasteful errors and improving capacity.

Read More

.png;maxWidth=300;quality=90)