-

-

SPONSORED

-

SPONSORED

-

Basics

How To Passivate Stainless Steel Parts

You've made sure the parts were machined to spec. Now, make sure you've taken steps to protect those parts in the condition your customer expects them.

Read MoreHow to Scale a Job Shop for Growth with Fewer People

Front office disorganization and poor shop floor communications don’t just reduce a job shop’s efficiency; they are a barrier to growth. Having the right kind of ERP system can be the key to improving profitability and scaling for future growth

WatchTurn-Mills 101

Turn-mills are a type of multitasking machine that can shorten cycle times and help facilitate lights-out machining for two common machining types.

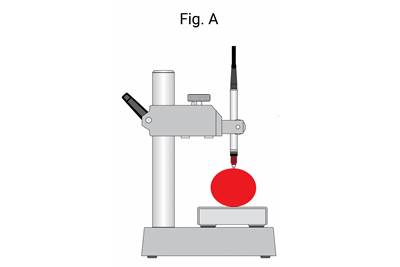

Read MoreHow to Improve Comparator Stand Performance for Gaging

Adding digital display systems and high-precision probes to comparator stands brings new functionality and pitfalls. The right setup can minimize errors.

Read MoreWorkholding 101

No universal workholding solution exists, so machine shop employees should have a basic understanding of multiple ways they can secure workpieces.

Read MoreWhat is Laser Cleaning? How Does it Work? EMAG Experts Explain

Lasers provide the flexibility to clean some areas of a CNC-machined workpiece while leaving others untouched.

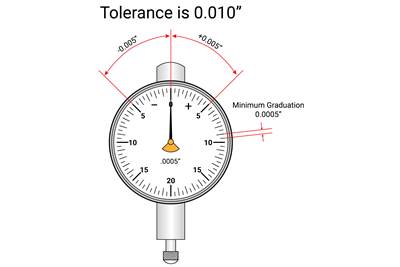

WatchHow to Choose the Right Dial Indicator

Digital alternatives are replacing dial indicators – but dial indicators can still be useful. Here’s how to select the right one for a given application.

Read More4 Ways “Tag and Track” Technology Keeps Data Chains Intact

Scannable images and tags inextricably link relevant information with workpieces, cutting tools and other physical assets.

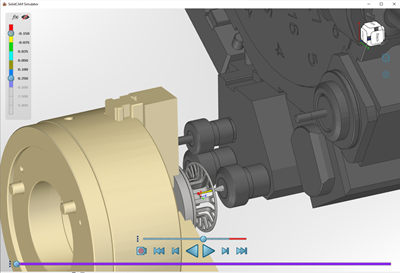

Read MoreHow to Get More Efficient Production from Swiss-Type and Multitasking Machines

SolidCAM for multi-axis Swiss type and multitasking machines provides a very efficient CAM programming process, generating optimal and safe Mill-Turn programs, with dramatically improved milling tool life.

WatchHow to Correctly Measure Surface Finish

When providing surface finish specs, engineers sometimes leave out the actual testing parameters. Here’s how to be sure measurements are as accurate as possible.

Read More

.png;maxWidth=300;quality=90)