-

-

SPONSORED

-

SPONSORED

-

Oil & Gas

Oil Drill Coupling Production Gets Automated

Sponsored by Okuma. A manufacturing cell combines lathes, gantry robot and conveyor system to enable automated production of oil drill couplings.

Read MoreCycle Shop Streamlines Startup With CAD-CAM

This start-up motorcycle manufacturer is an offshoot of Lucas Oil, a private oil marketer that supplies truckers, auto-racers and bike racers with oil formulations that are designed to offer protection while enhancing engine performance. Having already attended bike shows and racing events with its own promotional motorcycle, the company says it felt that introducing its own line of bikes and apparel seemed like a logical brand extension.

Read MoreSoftware Switch Leads To Improved Surface Finishes

MSI Products, a division of Dixie Iron Works (Alice, Texas) faces the challenge of building products with complex geometries for the oil- and gas-producing industries in relatively low volumes. The company struggled with programming software that was not able to import the complex assembly models needed to define its products or fully support the functionality of its CNC machine tools. This meant programmers had to define machine movements with lines of G code.

Read MoreSimplfying Thread Repair

Repairing damaged or worn threads on a workpiece is a common chore for toolroom lathes, especially in the oilfield industry. Haas Automation has a new feature for its conversational control units that simplifies and automates this process.

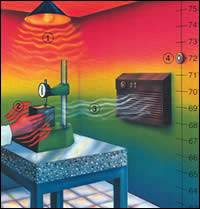

Read MoreGage Accuracy Runs Hot And Cold

“It takes a while to warm up in the morning, but after that, it runs great. ” I swear that machinists apply this statement to their gages as if the instruments were like car engines with 50-weight motor oil and cold-intake manifolds.

Read MoreSeparator Solves Tramp Oil Dilemma

Debco Machine, Inc. (Natick, Massachusetts), a job shop specializing in precision components from aluminum, plastics and stainless steel, was faced with what it characterized as a particularly demanding requirement for tramp oil removal from the sump of a Matsuura 510 vertical machining center, a machine that is in nearly constant use. About 1 gallon per day of tramp oil enters the 100-gallon coolant sump of this machine.

Read MoreAqueous System Handles Critical Parts Cleaning

At 200,000 rpm, even small chips in the oil passages of a turbocharger can hamper diesel engine performance. Engine manufacturers need precision parts cleaning and CNC machining.

Read MoreCNC Features Important For Lathes Used On Oil Valves

The company says it likes the CNC program test feature because each tool has its own geometry page and up to four offsets, making things less complicated.

Read MoreMilling System Keeps Valve Production Flowing Smoothly

Carbide inserts proved to be too slow in the milling of three Inconel high-performance alloys used in the manufacture of valve components for oil drilling and other industrial and commercial applications.

Read More

.png;maxWidth=300;quality=90)