-

-

SPONSORED

-

SPONSORED

-

Oil & Gas

Grinding Oil Improves Surface Quality

Blasogrind HC 5 from Blaser Swisslube is a high-performance grinding oil based on synthetic oil (hydro-racked oil). Applications include precision tool grinding, surface grinding, cylindrical grinding, fine profile grinding and lapping. Materials include steel; hardening and tempering steels; high speed steel; hard alloy; stainless steel; and carbide.

Read MoreInsert Provides Long Life, Short Cycle Times

Novatek, a manufacturer of diamond products used in the oil and gas, mining, construction and other industries, needed to reduce both costs and production time on a job involving very large workpieces. The Tiger-Tec black and gold WPP10 insert from Walter USA, which features an aluminum oxide coating designed to prolong tool life at high surface footages, helped the company increase feeds and speeds and create smaller, more manageable chips.

Read MoreYour Liquid Capital—A Dire Emergency

This article was written while “burning the midnight oil” because about 95 percent of this column’s readers who call me have a significant portion of their wealth being pummeled by the Wall Street meltdown.

Read MoreRing Groove Cutter Line

Designed specifically for the oil and gas industry, Greenleaf Corporation’s expanded Ring Max line of ring groove tooling is suited for difficult to machine materials. Combined with the company’s WG-300 or WG-600 whisker-reinforced ceramic inserts, the ring groove cutters can reduce cutting times from 30 min. to less than 1 min.

Read MoreSlotting Out A Niche In The Oil And Gas Industry

Designed for accurate slotting and grooving, Iscar's Tangslot cutter features tangentially mounted inserts that are said to improve tool life and chip evacuation. This tool was just what one Texas shop serving the oil and gas industry needed to reduce production costs and increase efficiency.

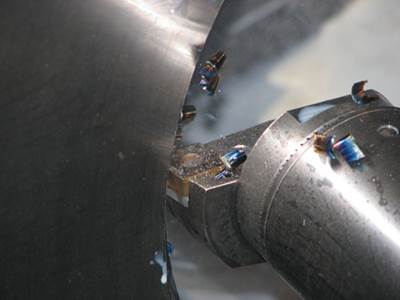

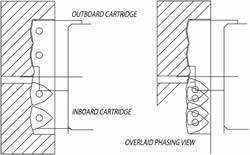

Read MoreNew Boring Tool Phases Out Multiple-Pass Operation

Boring large holes often takes multiple passes that lead to lengthy cycle times. This oil industry manufacturer turned to Allied Machine and Engineering for help with one such troublesome application. A custom tool saved the shop hours on cycle time.

Read MoreAutomated Production Of Oil-Drill Couplings

A machining cell combines lathes, a robot and a conveyor system to enable automated production of precision oil-drill couplings.

Read MoreThe Case For Hydrostatic Ways

Moving on oil can let a grinding machine deliver more power along a smoother pass.

Read MoreMeasuring Big: Lessons From The Oil Industry

In the world of oil drilling, there are some pretty big things. It's not just the rigs anchored out in the ocean that are huge: Everything that goes along with them seems to get supersized, including the need for gaging.

Read More