Five 3D Printing Trends Mirrored in Machining

The underlying drivers of additive manufacturing’s advance are increasingly easy to spot on automated CNC machine shop floors.

Share

Although HP’s Digital Manufacturing Trends Report is all about 3D printing, there is good reason why the document is not called the “Additive Manufacturing Trends Report.” All five of the identified trends are related in some way to digital technology, and digital technology is foundational to the advance of additive manufacturing. However, the same forces are also driving the advance of modern machine shops, regardless of their 3D printing capabilities. Viewed through the lens of a CNC machining business, the five trends are:

1. Accelerated Innovation. More than half of the surveyed executives cited “data and software” as the most important driver of this trend, which refers to “how 3D printing allows digital manufacturers to innovate, iterate and pivot fluidly in response to business demand.”

Survey data and 3D printing aside, CNC machine shops are unquestionably using data and software to innovate on multiple fronts. Machine tools are increasingly networked and monitored. Automated data transfer among tool presetters, CNCs and cell controllers, and even toolholders with embedded RFID chips can make lights-out machining more productive. Rather than a spreadsheet, shop floors are increasingly governed by enterprise resource planning (ERP) and other software, including predictive analytic systems that forecast future workflows and adjust processes accordingly.

2. Collaboration – that is, “forming new alliances and operating within new ecosystems” – was cited by more than 85% of respondents as being critical in the long term. Education is a particularly important focus of collaboration, with 64% of respondents reporting a desire for more professional training services to further 3D printing.

Digitalization is also driving the need for greater collaboration and improved education beyond 3D printing. The case is the same for machine shops, particularly defense industry contractors contending with the rollout of new Cybersecurity Maturity Model Certification (CMMC) requirements for data security. These shops are seeking services from consultants, managed service providers and others in addition to bolstering the knowledge and skills of their own personnel.

Concepts associated with so-called “factories of the future” are also starting to become tangible enough to affect how shops work with customers and vendors. To name one example, Lockheed Martin recently demonstrated the potential of digital twins, built from measurement data transmitted from the shop floors of many different suppliers, to provide part-feature-level traceability on complex assemblies.

3. Personalization and mass customization, at least at the levels detailed in the report, requires the kind of flexible, on-demand production that only additive manufacturing can provide. However, machining process flexibility is increasing, too. Even job shops with a high mix of low-volume work are automating with robot arms that are increasingly easy to integrate. This is thanks in part to advances in force sensors, vision sensors and intuitive programming.

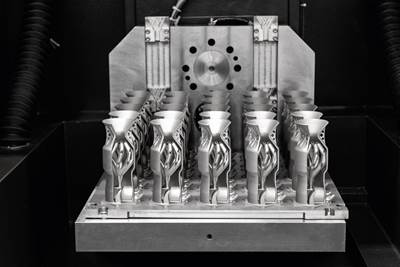

More machining businesses are integrating additive manufacturing for not just prototyping, but everything from shop-floor aids to robot-grippers to CMM fixtures like the one shown here.

Photo Credit: Advanced Precision Engineering (APE)

However flexible a shop’s own process, it might peddle its services along with those of a diverse array of other manufacturers on vetted, online networks that make customizing and personalizing easier for purchasers of machined parts. The basic idea is to dole out work according to members’ capacity and their capability, freeing time for both parts purchaser and manufacturer.

4. Sustainability is one potential benefit of these online networks. Distributed manufacturing, they promise, can make better use of overall capacity and keep part production local, among other benefits. This model is ideally suited for additive manufacturing, as demonstrated by the widespread, global sharing of 3D print files during the COVID-19 pandemic. Still, CNC machine shops already form a significant portion of many of these services’ members.

Consider Syncfab, a blockchain-based supply chain network that recently partnered with the National Tooling & Machining Association. Having collaborated closely with various local governments during the course of its development, Syncfab is an example “investment in and development of socially and environmentally beneficial technology,” which was cited as critical by 88 percent of the HP report respondents.

5. Economic Advancement. Although the trends identified in the HP report are easy to relate to machining, additive manufacturing stands apart in terms of its fundamental impact on how products are designed, produced and delivered. As such, it came as no surprise that the first trend listed in the HP report is survey respondents’ “nearly unanimous” assessment of digital manufacturing (i.e., 3D printing) as “a means to spur economies around the world.”

However, much of the technology’s impact is indirect, driven through its growing support of traditional processes like machining. For example, among the growth areas cited by the HP survey for 3D printing, half of respondents cited prototyping, design and development, while nearly a quarter cited tooling and/or molds. Machine shops might 3D print robot grippers, or perhaps CMM fixtures or assembly aids. To whatever extent additive manufacturing (and the underlying digital technologies) influences the evolution of a more sustainable, innovative, collaborative economy, machining will likely have a key role to play.

Related Content

Precision Shop Adopts Machine Monitoring, Boosts Revenue

Adopting machine monitoring helped LeClaire Manufacturing boost its vertical CNC utilization rates 38 percentage points and gain millions in revenue.

Read MoreMaking Machine Monitoring Matter

After seven years of inconsistent use, Pindel Global Precision needed to rethink how it used machine monitoring. From there, one change led to a 35% increase in utilization on its Swiss-type machines in three months.

Read MoreTurning the Corner on Virtual Machining and Simulation

Simulation software’s effectiveness comes down to proper implementation and alignment with shop priorities.

Read MoreBlueprints to Chips: CAD/CAM Tips and Tricks

This collection of articles delves into the latest CAD/CAM innovations, from AI-driven automation and optimized tool paths to the impact of digital twins and system requirements.

Read MoreRead Next

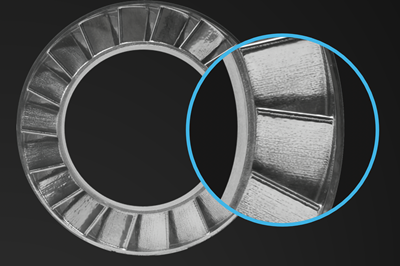

Cutting AM Parts from Build Plate Turns Wire EDM Upside Down

GF Machining Solutions found it had to modify nearly every aspect of a wire EDM machine to efficiently handle the challenges of removing 3D printed parts from build plates. Here is a look at a machine tool developed entirely for the needs of metal additive manufacturing.

Read MoreHere Is Why Knust Godwin Decided to 3D Print Mission Critical Parts

Knust Godwin introduced metal 3D printing into its precision-machining environment nearly eight years ago. Now the company is using the capability to break through into new applications and give 3D printed mission-critical parts a renewed business case.

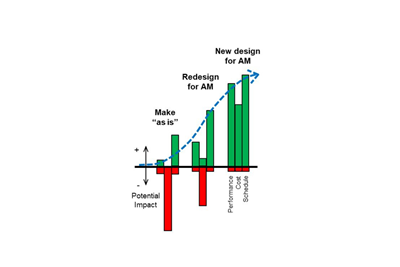

Read MoreBeginning the AM Journey: An Uphill Battle

Faster machines, cheaper feedstocks, new standards — with all of these advances, why is additive manufacturing still “an uphill battle” for so many?

Read More

.png;maxWidth=300;quality=90)