MMS Blog

Tips for Designing CNC Programs That Help Operators

The way a G-code program is formatted directly affects the productivity of the CNC people who use them. Design CNC programs that make CNC setup people and operators’ jobs easier.

Read MoreMetalworking Activity Stayed Consistent in July

Metalworking activity hung together better in July, with all but one GBI component contracting.

Read MoreProcess Control — Leveraging Machine Shop Connectivity in Real Time

Renishaw Central, the company’s new end-to-end process control software, offers a new methodology for producing families of parts through actionable data.

Read MoreFrom Tradition to Transformation: Century-Old Manual Machine Shop Adds CNCs

After 122 years of working with manual mills and lathes, this fifth-generation shop acquired assets of a local CNC machining business and hired the owner. Here’s how it’s going a year later.

Read MoreElectronic Bore Gage Automates Bore Data Acquisition

This new portable gage provides precision measurement and verification of custom parts with integrated data collection.

Read MoreThe Link Between CNC Process Control and Powertrain Warranties

Ever since inventing the touch-trigger probe in 1972, Sir David McMurtry and his company Renishaw have been focused on achieving process control over its own manufacturing operations. That journey has had sweeping consequences for manufacturing at large.

Read MoreRethink Quality Control to Increase Productivity, Decrease Scrap

Verifying parts is essential to documenting quality, and there are a few best practices that can make the quality control process more efficient.

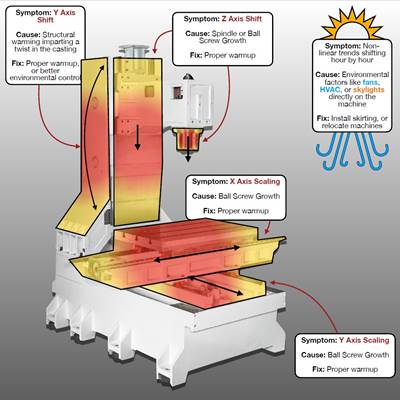

Read MoreHow Summer Heat is Affecting Your Parts

All machines have thermal shift. Follow these tips to keep your tolerances tight even as shop temperatures flucatuate in the warmer months.

Read MoreInverting Turning and Five-Axis Milling at Famar

Automation is only the tip of the iceberg for Famar, which also provides multitasking options for its vertical lathes and horizontal five-axis machine tools.

Read More5 Big Themes in Additive Manufacturing at Formnext Forum: Austin

Formnext Forum: Austin, a two-day event at the end of August focused on additive manufacturing for production, includes a conference exploring important ideas in AM related to supply chains, bridge production, enterprise transformation and more.

Read MoreHorizontal High-Speed Machining Saves Hundreds of Work Hours

High-speed machining is the latest change at Blair-HSM South, helping this once old-fashioned shop improve productivity and morale while enabling new work.

Read MoreKicking RaaS with Robotics as a Service

Robotics as a service (RaaS) enabled Behrens Manufacturing to quickly address a severe worker shortage while maintaining its ability to invest in new metal forming equipment.

Read More

.png;maxWidth=300;quality=90)