MMS Blog

3 TASC Topics That Touch on Automation Considerations for Job Shops

Automation is no longer a luxury in manufacturing today – it’s a necessity. The Automated Shop Conference (TASC) will connect job shops with experts who offer advice and considerations for this process.

Read MoreReceiving Honors and Actionable Feedback Through Top Shops

The Top Shops benchmarking program not only honors the best of the best, but it provides actionable data, enabling participants to recognize “how high is up.”

Read MoreConsiderations for Adding CMM Capabilities to Your Shop

CMMs may provide simple efficiency gains, but if you look deeper, the machine unlocks more complex work for your shop.

Read More4 Lessons Your Shop Will Take Away From TASC

The Automated Shop Conference (TASC) will give shops of all sizes and production volumes key insights and practical guidance on how to implement automation.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MorePay Attention to These 7 Themes at TASC

Looking to automate your shop floor? The Automated Shop Conference (TASC) will connect shops with experts who can advise them through this transition.

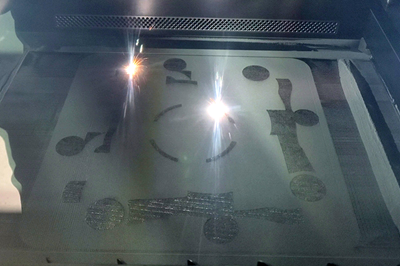

Read MoreDigital Thread Enables First-Time-Right 3D Printing

Connecting all stages of manufacturing, from design to postprocessing, helps break down barriers to industrializing additive manufacturing.

Read MoreFive Common Mistakes Shops Make with ER Collets (And How to Prevent Them)

Collets play a crucial role in the machining process, so proper tool assembly and maintenance is important. Here are five potential pitfalls to avoid when using ER collets.

WatchLearn How to Automate Your Machine Shop at 2023 The Automated Shop Conference

Attend TASC, The Automated Shop Conference, in Novi, Mich on Oct. 11, 2023 for a comprehensive look into how to use automation to transform your machine shop.

Read MoreBringing Machining In-House to Keep up With Demand for Offroading Parts

To meet demand increases for its Ford offroad industry components, supplier RPG Offroad brought its machining processes in-house, saving the company nearly $50,000 per month. Here’s how its choice of integrated CAD/CAM software made it happen.

Read MoreIncrease Savings and Streamline Purchasing Operations with Amazon Business

Machine shops and small manufacturers are finding cost and time savings using Amazon Business in their shops.

Read MoreShop Doubles Sales with High-Mix, Low-Volume Automation

Robots with adaptive grippers have opened entire shifts of capacity to high-mix, low-volume shop Précinov, doubling its sales.

Read More

.png;maxWidth=300;quality=90)