SCHUNK, Inc.

211 Kitty Hawk Drive

Morrisville, NC 27560 US

800-772-4865 | 919-572-2705

us.schunk.com

IS THIS YOUR COMPANY?

Video Gallery

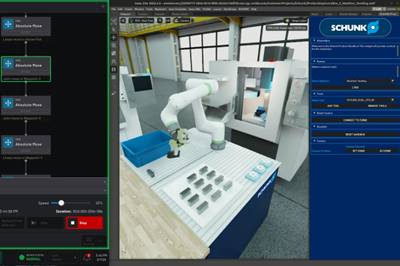

Inbetriebnahmevideo: Mechatronische Greifer im SCHUNK Control Center

Das SCHUNK Control Center ist eine übergeordnete Softwareplattform. Sie fungiert als zentrales Verwaltungstool für spezifische ...

The Healthy Factory

Wie Sie Ihre Prozesse produktiver gestalten und gleichzeitig Mensch und Umwelt entlasten. Was bedeutet es, eine "Healthy ...

CoLab Eröffnung in Österreich

Im neuen CoLab Roboter-Applikationszentrum von SCHUNK in Allhaming / Österreich werden konkrete Bearbeitungs- und ...

Einblicke ins CoLab: Sortieren und Ordnen von Bauteilen mit dem SCHUNK 2D Grasping-Kit

Sollen Produktionsprozesse automatisiert werden, erfordert das immer auch die definierte und sortenreine Bereitstellung von ...

As Seen On Modern Machine Shop

SCHUNK, Inc. Supplies the Following Products

Trade Names Offered by SCHUNK, Inc.

- KONTEC

- PGNplus

- TANDEM

- SINO

- TRIBOS

- PRISMO

- CELSIO

- SRU-plus

- FORTIS

- ACURO

- PZNplus

- SCHUNK VERO-S

- MAGNOS

- ROTA

- SCHUNK

- TENDO