-

-

SPONSORED

-

SPONSORED

-

Basics

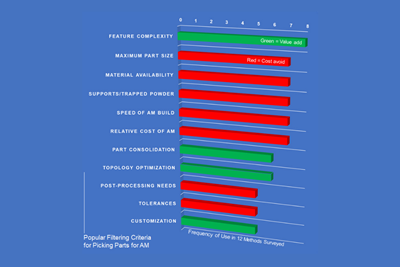

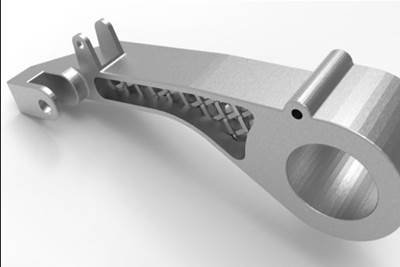

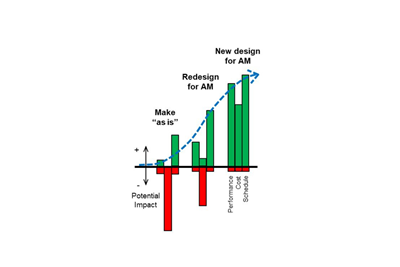

Beginning Your AM Journey: One Part to Begin the Path

Identifying the right part to begin your additive manufacturing path can demonstrate and validate the AM workflow, provide a benchmark for future work and more.

Read MoreWhy Fast Quoting Delivers Better Business Opportunities

Shops that can’t respond quickly to RFQs may be spending hours quoting jobs that are already gone. It’s wasted time and lost opportunity. Here’s what you can do about it.

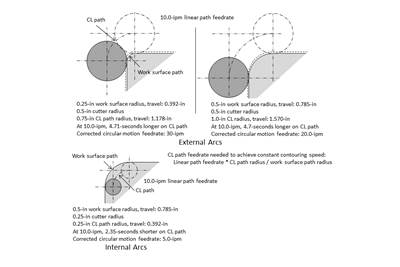

Read MoreHow to Modify Feed Rate for Circular Motion Commands

Maintaining a constant feed rate between linear and circular milling easily leads to chatter — for most applications, increase feed rate on external arcs and decrease it for internal.

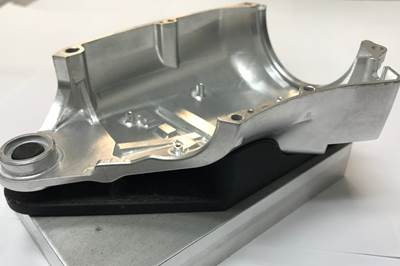

Read MoreFive 3D Printing Trends Mirrored in Machining

The underlying drivers of additive manufacturing’s advance are increasingly easy to spot on automated CNC machine shop floors.

Read MoreAvoiding a Failed Automation Integration

New features that simplify robot use have blurred the lines between tasks that shops can automate independently from those that will require the support of an integrator. Here’s what shops should keep in mind to avoid a costly failed integration.

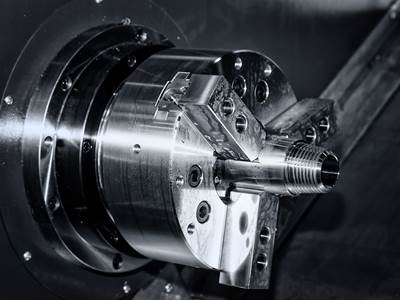

Read MoreHow to Save Time When Mounting Jaws on Three-Jaw Chucks

Precisely placing jaws on three-jaw chucks for CNC turning machines is difficult, but a laser pointer and clever programming can ease the issue.

Read MoreHow Do Binder Jetting and Multi-Laser Powder Bed Fusion Match Up?

Both metal 3D printing processes are ready for production, but which wins out for speed and cost? Research from The Barnes Global Advisors offers a case study.

Read MoreBeginning the AM Journey: An Uphill Battle

Faster machines, cheaper feedstocks, new standards — with all of these advances, why is additive manufacturing still “an uphill battle” for so many?

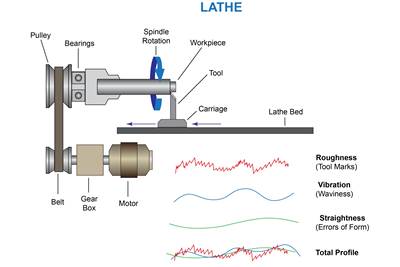

Read MoreWhat to Know About Decoding Surface Finish Gages and Parameters

Long-wavelength waviness and short-wavelength roughness require a wide variety of instruments and parameters for proper measurement — and lower numbers aren’t always better.

Read MoreStarting with the End in Mind: An Exit Strategy for Machine Shops

John Shegda and Eric Wilhelm each had different ideas about how they wanted to phase into retirement. The exit strategies for the three successful manufacturing businesses the two men operated included a mix of seeking equity groups, selling the business, or transitioning into an employee stock ownership plan. All it took was a friendly suggestion from a mutual friend to set them on a different path.

Read More

.png;maxWidth=300;quality=90)