-

-

SPONSORED

-

SPONSORED

-

High-Speed Machining

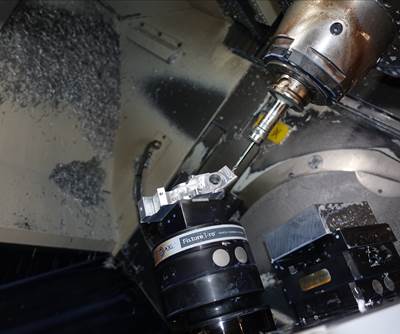

Hitting the Zone with Five-Axis Machining

By investing in five-axis machining technology, Advance CNC Machining has done more than just add new capabilities to its roster. It has found a way to achieve something that most of us strive for: a way to work “in the zone.”

Read MoreComposites Specialist Makes CNC Chops Count

Machining capability drives evolution from race car builder to aerospace and defense contractor.

Read MoreHMC Features High Speed, Smaller Footprint

Sold and serviced by Absolute Machine Tools, the HMC is intended to be a low-cost, high-speed machining center meeting the demands of manufacturers with high-volume machining needs.

Read MoreStudy Finds Brass Has Profit Potential for High-Speed Machine Shops

For machine shops with high-speed equipment already on the floor, brass represents an opportunity to capture new profits they might otherwise miss with other materials, according to the study.

Read MoreHigh-Speed Graphite Mill Features Temperature Compensation

GF Machining Solutions’ high-speed Mikron Mill S 400/500 Graphite and Mikron HSM 500 Graphite are dedicated specifically to graphite machining.

Read MoreStarrag Tech Days Highlight Turbine Technology Applications

A visit to Starrag headquarters in Roschacherberg, Switzerland during the company's 2018 technology days revealed new equipment, tools, technologies and machining strategies for turbine manufacturing.

Read MoreMachining Parts for the World’s Largest Digital Camera

SLAC is building the world’s largest digital camera, to be installed inside the Large Synoptic Survey Telescope. Getting there requires the machining expertise of shops like Keller Technology.

Read MoreMMS Looks Back: 1990s - High-Speed Strategies for a High-Speed World

Amid rapid advances in information technology, machines and tools designed for more powerful controls and more capable software enabled shops of the 1990s to mill faster than ever before. This story is part of our 90th anniversary series.

Read MoreHardware for High Metal Removal Rates

Spindle power and shrink-fit toolholding are two assets this shop seeks to use to the extremes of their capabilities.

Read MoreAdding Context to Advanced Milling

For all its focus on machines, cutters, parameters and tool paths, an expo hosted by Methods Machine Tools demonstrated that competitive hard milling increasingly requires looking beyond the workzone and even beyond traditional machining.

Read More

.JPG;maxWidth=400;quality=70)

.png;maxWidth=300;quality=90)