-

-

SPONSORED

-

SPONSORED

-

High-Speed Machining

Maximizing Power for High Speed Hog-outs

A reader asks a question related to the rated power of a machine tool spindle.

Read MoreImproving Surface Finish During High Speed Machining

Many factors can affect surface finish. This answer to a reader’s question focuses on imbalance and frequency sensitivity.

Read MoreThe Online Optimizer

Coming soon: The Machine Tool Genome Project promises to let almost any machine shop use its machining centers more productively. Shops will benefit from tap-test findings without personally tapping any of their own machines or tools.

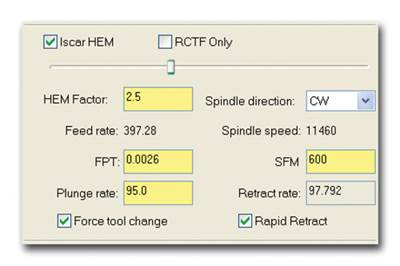

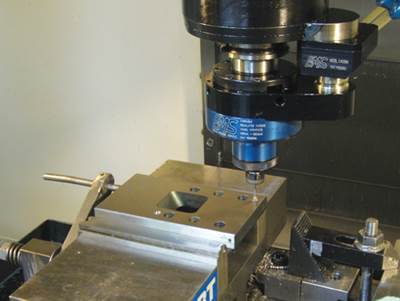

Read MoreSoftware/Tooling Partnership Promises Easier HSM

High-efficiency parameters are calculated automatically—partly using a slider that lets the programmer set the level of aggressiveness.

Read MoreMilling with Air

... not to mention grinding with air. Thanks to high speed spindles powered by shop air, this job shop expands the work its VMCs can do.

WatchHow to Overcome an Acc/Dec Limitation in High Speed Machining

A small pocket in a graphite workpiece limits productivity. Part of the expert’s response is to consider how a lower feed rate might actually be more productive—because the machine will spend more time at the programmed rate.

Read MoreBasic Questions on High Speed Machining

Can HSM apply to turning? Does the “speed” refer to cutting speed or spindle speed? What is the explanation behind lower forces and lower heat generation?

Read MoreHard Milling Isn’t Just High Speed Machining

Milling complex forms in hardened tool steel involves more than just fast, light cuts, says this maker of medical-related injection molds. Here are some of the ingredients of an effective hard milling process.

WatchAnother Angle On HSM

The savings in setup time were welcome enough, but this mold maker found that a 3+2 machining center also accelerated its use of high speed machining.

Read MoreTool for Shallow, High-Feed Cuts Speeds Roughing

“Feed fast, cut shallow.” This strategy, in combination with a cutting tool specifically designed to take advantage of it—the Power Feed+ from Ingersoll—enabled this shop to reduce cycle time on a tough prototyping job by a factor of five and increase insert life by a factor of six.

Read More

.png;maxWidth=300;quality=90)