Okuma America Corporation

11900 Westhall Drive

Charlotte, NC 28278 US

704-588-7000

okuma.com

IS THIS YOUR COMPANY?

Video Gallery

Automation 101: Fastems Pallet Towers That Do It All

Let Wade Anderson and Ian Sandusky help you realize that almost any automation configuration is possible as they explore pallet ...

IMTS 2024: A Week Like No Other

Six days. Endless opportunities to explore. We're bringing everything to IMTS 2024 to turn these opportunities into realities, ...

CNC Control: OSP-P300 & P500 Comparison

Curious about the new Okuma OSP-P500 control? Discover the popular features we carried over from the OSP-P300, as well as ...

Okuma MVP [Most Versatile Products] Days: Tempe, AZ on April 11, 2024

Please join us at the upcoming Okuma MVP [Most Versatile Products] Day event in Tempe, AZ, on Aril 11, 2024! This event will be ...

As Seen On Modern Machine Shop

Editorial, News, and Products

-

Protecting Your Automation Investments

Shops need to look at their people, processes and technology to get the most of out their automation systems.

-

Where Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

-

Okuma America Corp. Appoints New VP of Engineering & Factory Automation Group

Wade Anderson will lead Okuma America Corp.’s engineering department, which includes applications engineering, product engineering and quality assurance teams.

-

Okuma America Control Features Digital Twin Technology

The OSP-P500 control features dual-core processors that provide redundant operations, ensuring uninterrupted machining operations.

-

Emuge-Franken USA Partners With Okuma America

Okuma’s Partners in Technology program is a collaborative network of more than 50 companies that provide distinctive technologies and services that augment Okuma CNC machines for metal cutting and manufacturing applications.

-

Okuma America Receives Workplace Recognition Awards

The company has received two awards from Top Workplaces, an employer recognition organization.

-

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

-

Translating a Prototyping Mindset to Production

The experimental mindset that benefited BDE Manufacturing Technologies as a prototype job shop has given it an adaptable edge as a production facility.

-

Okuma America Corporation Launches Automation Business Segment

The company will offer customers a broad range of Okuma machine tools and automation system pairings.

-

Four-Axis Horizontal Machining Doubles Shop’s Productivity

Horizontal four-axis machining enabled McKenzie CNC to cut operations and cycle times for its high-mix, high-repeat work — more than doubling its throughput.

-

Okuma Demonstrates Different Perspectives on Automation

Several machine tools featured at Okuma’s 2023 Technology Showcase included different forms automation, from robots to gantry loaders to pallet changers.

-

Integration, Automation and Green Tech Highlight JIMTOF 2022

Known as one of the largest machine tool trade shows in the world, the Japan International Machine Tool Fair (JIMTOF) has a reputation for being a machining technology show more than a machine tool sales event. And this year’s show in Tokyo — the first in-person Japanese machine tool trade show in four years — did not disappoint.

-

Okuma America Corporation Recognized as a Top Workplace in 2022

The Charlotte Observer granted a 2022 Top Workplace distinction to the company based on a survey that polled 24 different topics related to job satisfaction and company culture.

-

Okuma America Double-Column VMC Features Compact Footprint

The new Genos M560V-5AX offers a working envelope with a 500 mm table and wide axis travels, while still maintaining a compact footprint of 2,515 mm × 3,750 mm.

-

Tool and Die Shop Discovers New Opportunities With First CNC Machine

In a shop that stamps millions of parts per year, the arrival of a CNC machining center is opening new pathways for production and business.

-

Inside an Amish-Owned Family Machine Shop

Modern Machine Shop took an exclusive behind-the-scenes tour of an Amish-owned machine shop, where advanced machining technologies work alongside old-world traditions.

-

A Show That Bucks the Status Quo

IMTS 2022 - The International Manufacturing Technology Show will feature more than the latest metalworking technologies. It will provide a strong case to American manufacturers that now is the time to bring production back home to the United States.

-

Wide Range of Applications for Horizontal Machining Center

The MA-8000H joins Okuma America Corp.'s lineup of horizontal machining centers with applications from heavy-duty to high-feed machining.

-

Wide Range of Applications for Horizontal Machining Center

The MA-8000H joins Okuma America Corp.'s lineup of horizontal machining centers with applications from heavy-duty to high-feed machining.

-

Vertical Lathe Executes Heavy-Duty, Long and Continuous Cutting

New VT1000EX Vertical Lathe from Okuma America Corp. possesses the capability to cut and machine difficult materials through, according to Okuma, its highly rigid, mechanical configuration, extreme thrust and torque.

-

Preparing a Shop for Automation

Ensuring a stable, predictable production process can prevent automation from multiplying existing problems.

-

Morris Group, Okuma America Open Technical Center

New joint facility in Elgin, Illinois, will serve as a product showroom and technical center for machine tool users in the midwest.

-

Horizontal Machining Center From Okuma Offers New Features

The new machining center offers a larger work envelope, enhanced chip and coolant management functions and automation compatibility, among other features.

-

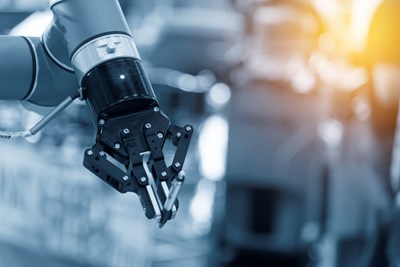

Choosing the Right Automation for Your Shop

This robotic arm Is fully integrated into the machine tool, enabling machine tool operators with no previous robotics experience to operate it effectively.

-

Four-Flute Carbide Drill Increases OWSI's Feedrate Fourfold

Ceratizit’s line of WTX-HFDS drills saved OWSI 3.5 minutes per part on a difficult job and completely eliminated a secondary operation, increasing profitability.

-

Okuma Launches Conversational Programming on Select Machines

Okuma has launched its Advanced One Touch-Interactive Graphics Function (AOT-IGF) conversational programming software on select machines, increasing usability and speeding up setup times.

-

Okuma’s MCR-S Roughs, Finishes Press Dies in One Setup

Okuma's MCR-S double-column machining center reduces cycle time to rough and finishing press dies in one setup.

-

Growing a Job Shop into a Full-Service Manufacturer

By maximizing employee satisfaction, adding fabrication and other services, and always keeping open machine capacity, Square Deal has grown from a seven-person job shop to a full-service manufacturer that employs hundreds.

-

CNC Machine Shop Reaps Benefits of Hiring an IT Person

A database guru combined off-the-shelf technology with an elaborate proprietary shop management software to drive efficiency throughout all areas of a machine shop.

-

Manufacturing Association Aids Shop’s Pivot to Ventilator Parts

After reaching out to the Austin Regional Manufacturers Association, a shop that typically serves oil and gas and heavy industry was able to quickly fill an order for ventilator parts.

-

Sometimes the Trickiest Part of CNC Machining Is Holding the Part

Finding a way to fixture contoured marine propellors proved to be this shop’s biggest challenge in developing an effective automated machining cell.

-

Okuma's Genos M660-V VMC Handles Large Workpieces in Small Footprint

Okuma’s Genos M660-V vertical machining center combines a large work table, a compact machine footprint and a CAT 40 Big-Plus spindle for machining large, complex parts.

-

Taking an Automated Aerospace Approach

A flexible manufacturing system helps an Indiana job shop run a high mix of aerospace work for long stretches of time and function more like a contract shop.

-

Metalworking News of Note: November 2019

Orderfox.com adds an RFQ service for its users, Sandvik Coromant begins construction on new tech center in North Carolina, and other news from the metalworking industry.

-

What Can 5-Axis Machining Do for Your Shop?

If you haven’t looked at 5-axis machining lately, a lot has changed. Advancements in 5-axis machines, controls and software have made this technology so affordable and easy to use that it can benefit almost any shop.

-

Fabricator's Toolroom Becomes Captive CNC Machine Shop

Toolroom problem-solving yields high-production profit when a sheet metal fabricating business accepts a difficult machining contract.

-

Okuma Announces New Standard Warranties on Machines, Controls

The standard warranty now includes coverage for all Okuma core and high-tech products as well as OSP and FANUC controls.

-

Your Competitors Can Do What You Do

With the barrier to entry for machine shops so low, competitive advantage is not necessarily tied to the ability to machine parts. Increasingly, it is a shop’s ability to document and streamline digital processes that sets it apart from competition.

-

Is Robotic Automation the Key to Drawing (and Keeping) New Employees?

Robotic automation is transforming a job that was perhaps a machine operator’s least-favorite work assignment into one that is not a heavy lift.

-

Horizontal Machining Plus Automation Prove to Be a Rewarding Investment

After watching a machinist take four hours to set up a part on a VMC, Dan Olsen of Mach Machine knew he had a problem. The solution seemed clear: horizontal machining. The automation system wasn’t expected; but the novelty was well worth it before long.

-

5 CNC Apps Simplify Machine Shop Routines

Whether purchased online or made to order, custom control functions help a contract machining startup save time and avoid mistakes.

-

Boring Head Enables Sculpture Hardware to Be Machined on a Lathe

When small job shop Ansonia Manufacturing took on a tricky hardware component job for a “live” glass art sculpture, it realized a boring head would be needed to machine the part complete on its live-tool lathe.

-

Three Expectations for Robotic Automation

Shops take some modern robot capabilities as given, but a recent trade show in Japan demonstrated ways those capabilities continue to improve.

-

The Unattended Effects of CNC Machine Shop Automation

Automated machining and data collection have helped Custom Tool to not only grow its business through more lights-out production, but also to establish a continuous-improvement mindset that has enabled it to become more efficient in numerous areas.

-

New Okuma Hybrid Brings New Possibilities in Additive, Five-Axis and New Materials

The machine stands as an example of process automation within a booth showing other automation examples such as adjacent machine tools performing trunnion-to-trunnion handoff.

-

Shop Works to get the Most Out of Its Five-Axis Capabilities

Vertical machining centers with rotary tables helped this Indiana job shop set itself apart, but specific machine features and additional equipment have helped it use them more efficiently to grow its business.

-

Top Shops Winners Talk Technology, Tactics

Successful machining businesses implement effective processes and strategies both on the shop floor and in the front office. Recent chats with representatives from this year’s award-winning Top Shops shed light on some approaches they have leveraged to their advantage.

-

Open Mind Joins Partners in THINC

Okuma and Open Mind have collaborated on four- and five-axis projects for various Okuma machines.

-

Okuma’s LU7000EX Handles Large Parts with Ease

Okuma America Corp., a leading builder of machine tools, announces the debut of the new LU7000 EX, which is great news for manufacturers in the oil and gas industry.

-

MU-S600V Connects Machines and Enables Built-In Robotics

Okuma America Corp.’s MU-S600V five-axis vertical machining center achieves maximum productivity with the ability to connect multiple machines.

-

Machining Center Combines 5 Axis Milling with Laser AM

IMTS 2018: Okuma America Corp.’s MU-8000V Laser EX multitasking machine combines five-axis machining with a Trumpf laser.

-

NTMA Members Spotlight Shop Additions

While traveling with some members of the National Tooling and Machining Association, a few highlighted recent improvement efforts from which their operations have benefited a good deal.

-

CNC Lathe Line Features Range of Spindle Motors

IMTS 2018: Okuma America’s LU7000 EX two-saddle CNC lathe has a wide range of spindle motor specifications for manufacturing large parts.

-

Machining Technology Trip to Japan

A recent trip with NTMA members to Okuma and Big Daishowa manufacturing facilities provided the opportunity to learn about their in-house production capabilities and new machining technology offerings.

-

Laser EX Combines Traditional Machining with Laser Metal Deposition

Okuma America Corp. introduces the MU-8000V Laser EX. A super multitasking machine that combines five-axis machining with a Trumpf laser to provide state-of-the-art laser additive technology.

-

Two-Saddle Turning Center for Large Energy, Aerospace Parts

IMTS 2018: Okuma America’s Multus U5000 two-saddle CNC lathe handles large parts for the energy and aerospace industries

-

Affordable Five-Axis Machining

Okuma America Corporation’s Genos M460V-5AX is a five-axis vertical machining center making its debut at IMTS.

-

Using Data to Do Better in Manufacturing

Although the Smart Manufacturing Experience 2018 event in Boston may not have provided a simple, clear definition of “smart manufacturing,” it did provide a broad experience of what smart manufacturing can be like.

-

May 2018 Product Spotlight: Machining Centers

This month’s Modern Equipment Review Spotlight focuses on a variety of vertical, horizontal and five-axis machining centers, some with dual spindles.

-

VMC Enables Precise Five-Axis Machining

Okuma’s MU-5000V vertical machining center is suited for five-axis, multi-sided machining.

-

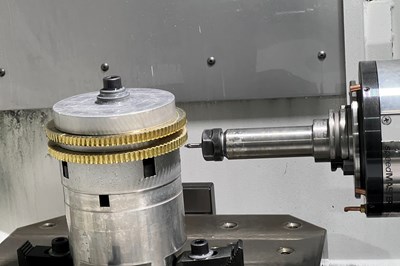

Evolution of Performance Camshaft Grinding, Finishing

Comp Cams has made numerous improvements to its CNC camshaft grinding process. The company has also implemented what it calls its “Micro Surface Enhancement” finishing technology, which works in tandem with its enhanced grinding process to further improve camshaft longevity and durability.

-

Five-Axis VMC Increases Accuracy by Reducing Vibration

Okuma America has released the five-axis Genos M460V-5AX vertical machining center with rigid, cast iron, double-column construction and a high-speed spindle.

-

Hybrid Machine Combines Laser AM with Subtractive Processes

The hybrid multitasking machine tool combines traditional CNC machining with laser metal deposition capabilities.

-

What Does It Take to Succeed at Machining Hogouts?

Beyond the machining capacity, other important factors relate to the people and the understanding of the process.

-

An Automation System for a Job Shop Environment

A flexible robotic part-loading and unloading system enables a small Indiana shop to boost production without a large investment.

-

Partners in THINC Winter Showcase to Demonstrate Five-Axis Setup

The demonstration is intended to benefit shops that need to do five-axis work but don’t want to or need to incur the price of a dedicated five-axis machine tool.

-

Taking the Drag out of Automotive Machining Setups

Paired with the right cutting tools, workholding and software, multi-tasking and multi-axis equipment enables this race team to also bill itself as a full-fledged parts supplier.

-

Applying Automotive Machining Lessons to Aerospace

Although motorsports are a natural focus for a shop owned by a former NASCAR driver, five-axis machining and an emphasis on process planning have opened the door to new aerospace work.

-

Twin-Spindle Lathe Includes Three-Axis Gantry Loader

Okuma’s 2SP-150H horizontal twin-spindle lathe offers high metal removal rates in a small space and is ideal for small-part CNC machining.

-

Expanded Range of Multitasking Hybrid Machine Tools

The machining centers combine laser metal deposition with a range of subtractive processes.

-

HMC for Large Aerospace Parts

Okuma’s MA-12500HW horizontal machining center is designed to provide a balance of speed and cutting power in difficult materials like cast iron and aluminum alloys.

-

Why Machine This Boxy Part on a Lathe?

South Morgan Technologies has long thrived on its ability to mill boxy parts on a turning platform. Today, newer technology and techniques enable saying “yes” to more work than ever before.

-

Manufacturing News of Note: January 2017

Okuma showcases IIoT-enabled technologies, a large welding machine is getting developed for lightweighting R&D, and other industry news.

-

JIMTOF 2016 Report: Exhibitors Show a Strong Embrace of IIoT

The recent Japan International Machine Tool Fair reflects the rapid move toward smart factories in which smart machines are fully networked.

-

Okuma Hosts 400 at Annual Technology Showcase

The event’s theme focused on the Industrial Internet of Things (IIoT).

-

Vertical Lathe Precisely Machines Large, Heavy Parts

Okuma’s V920EX single-saddle vertical lathe features a powerful turning spindle and a larger work envelope, making it ideal for cutting a variety of large, heavy parts.

-

JIMTOF: A Strong Embrace of IIoT

The recent Japan International Machine Tool Fair reflects the rapid move toward smart factories in which smart machines are fully networked. Japanese providers of manufacturing technology have clearly embraced the concepts of the Industrial Internet of Things.

-

Cell Automates Multiple Part Change-Overs

An automated work cell on display in Okuma’s Booth S-8500 demonstrates not only robots loading and unloading parts, but also automated production run change-overs.

-

Optimized Machining out of the Box

Four tooling-related companies partner to supply dynamically stable milling for improved productivity on existing machine tools. Users do not have to measure the dynamics of their machines. Instead, tooling tailored to the machine arrives as a complete assembly, along with software for quickly determining the parameters that tooling can be used to achieve.

-

Automation Evangelists Cast Wide Net

This recent event was hosted by a network of suppliers in a single location touting a single message: Automation isn’t necessarily time-consuming and expensive, even for smaller shops.

-

Webinar: Additive and Subtractive Manufacturing for Productivity

An upcoming webinar presented by Okuma and RPM Innovations will address AM’s role alongside subtractive manufacturing.

-

High-Throughput Cell Segregates Additive, Subtractive Processes

Two industry suppliers say cells combining separate, dedicated equipment can outperform hybrid machines in high-volume industrial applications.

-

March 2016 Product Spotlight Slideshow: Machining Centers

This month’s Modern Equipment Review Spotlight focuses on horizontal, vertical and five-axis machining centers.

-

Hot Chips in Ohio

Honoring the past while planning for the future, this entrepreneur launched a machine shop on the family farm, tending the cattle while manufacturing components.

-

CNC Grinder Series Supports High Production

Okuma’s GPW/GAW grinder series is now equipped with the company’s intelligent OSP-P300G CNC control.

-

Using an App to Adopt CNC Technology Faster

Learn about a company that made the leap into CNC technology thanks to a custom machine-operating/program-generating app that enabled its inexperienced people to effectively run its new CNC turning center.

-

Shop Applies App to Adopt CNC Technology Faster

A custom machine-operating and automatic program-generating app has helped racing parts maker Moser Engineering quickly reap the benefits of CNC machining even though nobody there had any prior experience with it.

-

Aztalan Aims for Rapid Adjustment

Aztalan Engineering shortened its lead times by switching to a short-run cell model for its prototype jobs and implementing a company-wide QRM strategy.

-

The Art and Science of Hand-Scraping Ways on CNC Machine Tools

Hand-scraping the mating surfaces of a CNC machine tool’s motion system offers myriad advantages.

-

Want to Test Drive Cryogenic Technology?

Okuma and 5ME have opened two test centers where you can give cryogenic machining (using liquid nitrogen as the coolant) a shot.

-

Five-Axis VMC Supports Consistent, Safe Work with Difficult, Heavy Workpieces

Okuma’s MU-8000V vertical machining center performs five-axis, multi-sided machining.

-

Okuma Supports Aerospace Excellence

The new Aerospace Center of Excellence at Okuma America enables manufacturers to visit, test equipment, confer with experts and learn about CNC machines that are custom-designed for aerospace industry applications.

-

VMC Accommodates Large, Heavy Workpieces

The base column of Okuma’s Millac 852V II vertical machining center features ribbing to counter chatter and twisting during heavy-duty cutting.

-

Secrets to the Art of Hand Scraping

Hand scraping of mating surfaces on a machine tool enables the surfaces to be flatter, more accurately aligned, longer wearing and freer to glide across one another. No automated or mechanical operation can match these benefits. Machine builder Okuma explains how this seeming paradox is true.

-

Making Sure MTConnect Is a Good Fit

An MTConnect-enabled machine monitoring system gives shopfloor managers information that is driving up utilization rates and improving workforce communication for this manufacturer of high-pressure aerospace fittings.

-

March 2015 Product Spotlight Slideshow: Machining Centers

Click through this slideshow for HMCs, VMCs, multitasking centers and more.

-

Multitasking CNC Lathes Minimize Noncutting Time

Okuma’s Multus U series multitasking CNC lathes are capable of gear machining, skiving and hobbing operations.

-

The Case for Off-Site Innovation

Okuma says the point of its aerospace technology center is to provide a place for manufacturers to perform all the trial-and-error they need to perfect a new process. It’s also a place to find and consult with sources of up-to-date manufacturing technology expertise.

-

Okuma’s Aim Is True

This video series about how the company’s CNC machines are used to manufacture gun parts sets its sights on opportunities to enter a booming market.

-

VMC Offers High Rigidity, Heavy Cutting Ability

The Millac 852V II vertical machining center from Okuma is well-suited for machining large, heavy workpieces.

-

Tooling Selection Keeps Big Aerospace Component In-House

Attention to the tool-up process enabled JWF Industries to launch a large-scale defense industry radar frame project, keeping production in-house and ultimately shaving weeks off of the expected production time.

-

VMC Equipped with FSM for Unattended Operation

Okuma will display its vertical machining center equipped with a Palletace flexible manufacturing system (FMS) for unattended operation.

-

The Costs and Benefits of Horizontal Machining

The shift from vertical to horizontal machining was even more expensive than this shop anticipated. It was also more valuable. Most of the shop’s machining centers are HMCs now—here’s why.

-

Multitasking CNC Lathes Reduce Setup Times

Okuma’s Multus U3000 and Multus U4000 general purpose multitasking CNC lathes are intended to reduce setup time, improve accuracy and limit non-cutting time.

-

Turning Center Enables Off-Center Machining

Okuma’s Genos L300-MY turning center features a Y axis for off-center milling, drilling and tapping capability.

-

120-Meter Long FMS in New Okuma Plant

With a broad product line and the need to meet tight delivery requirements, machine tool builder Okuma faces a challenge many of its customers would recognize. Namely: the need to manufacture responsively in an environment of high product variety and low production volumes.

-

New Okuma Plant Relies on Automation, Production Control

The company says the DS1 facility in Japan is capable of 2 times the production capacity and 1/2 the lead time of the previous site.

-

Horizontal Lathe Promotes Stability

Okuma’s Genos L250E horizontal lathe offers an 8" chuck with an 8.26" maximum turning diameter and accommodates workpieces as long as 500 mm (19.69").

-

This Blog is about Vlogs

Vlogs? That's the common name for video-blogs. Okuma America Corporation has launched a series of these educational videos on its YouTube channel that covers timely topics and practical tips for improving shop floor productivity.

-

5 to 10 for 5

An auto tuning option for Okuma five-axis machines is said to reduce tuning time for geometric errors from five hours to just 10 minutes.

-

Automation at Aztalan Engineering

A contract manufacturer expands its capacity using various approaches to feeding the machines.

-

Cell Designed for Aluminum Wheel Manufacturing

The All-Okuma wheel cell for cutting and drilling aluminum wheels is designed to increase productivity and efficiency while minimizing downtime.

-

Lathe with Multitasking Capability Helps Shop Stay Competitive

Purchasing a multitasking turning center has helped Mercer Machine Tool accept a wider range of jobs to ensure the future of its business.

-

Where Grinding Still Beats Hard Turning

For many critical applications, grinding remains the optimal machining process.

-

When Reshoring Really Happens

Bob’s Design Engineering illustrates how a shop that used to be organized for short-run work transformed its process for ongoing production.

-

What JIMTOF Had to Show Us

We present here some of the interesting and visually appealing snapshots from JIMTOF 2012.

-

Managing Machining’s Thermal Effects

Thermal growth is an inherent factor in any machining process. Here's how one company constructs its machines to adapt to changing thermal conditions.

-

More Effective Camshaft Machining

A leading manufacturer of high-performance valve train components installed a twin spindle/twin-turret lathe to bring camshaft machining work in-house. Here, the company explains how it has become more effective using its multifunction lathe to produce small batches of custom racing camshafts.

-

Delivering Value in Program Production

A contract manufacturer specializing in ongoing production programs describes the investments involved in winning this work.

-

Making Lean Connections

When Nilpeter embarked on a lean initiative 14 months ago, no one at the printing press manufacturer had any inkling that they had already taken an important first step.

-

Cycle Efficiency

Automated machining processes enable this maker of high-performance mountain bike parts to manufacture efficiently with minimal staff.

-

Disaster in Japan: A Spirit of Generosity Will Prevail

Despite last week’s horrendous disaster, Japan will carry on.

-

What It Takes for Oilfield Success

Hunt and Hunt’s president says adopting turn/mill machines was one of the most challenging endeavors his 55-year-old shop ever undertook. He also says it’s the best thing the shop could have done to become more efficient at contract work.

-

Double-Column VMC with Small Footprint

The M460-VE VMC features a double-column structure for increased machining capability in reduced floor space, the company says.

-

Saving Labor Also Safeguards Labor

A manufacturer that aims to expand its workforce, without a high risk of layoffs later, sees pallet cells that can run through the night as being key to this goal.

-

Aluminum Molds In Three Weeks Or Less

While aluminum molds are commonly used to create prototypes or to serve as stopgap bridge tooling, they are starting to receive greater attention for production work. This shop’s approach to creating aluminum molds in one day to three weeks is the same for each of these situations.

-

The Part Is Longer Than The Lathe

Here is one custom machine builder’s system for producing a 40-foot part that has to be passed through the turning center and out the other side. INCLUDES VIDEO.

-

Automated Production Of Oil-Drill Couplings

A machining cell combines lathes, a robot and a conveyor system to enable automated production of precision oil-drill couplings.

-

Thinking About Shopfloor Interoperability-And Making It Happen

The significance of “plug-and-produce” integration for machine shops and manufacturing plants becomes clear from the perspective of an ERP software developer.

-

Machine Tools Used As Dedicated Equipment…For A Little While

Two keys to this shop’s success are versatility and speed. It uses flexible machining centers, rather than dedicated equipment, and constantly reconfigures them into new cells for new jobs. The speed at which it can do this, in addition to in-house tombstone manufacturing capability, provides the nimbleness to quickly respond to its customers’ needs.

-

Machining Center Tool Eliminates Camshaft Burrs

A special tool performs burr removal inside the part where holes intersect.

-

Hard Milling With Tandem Toolholding

A combination of toolholding choices lets this die shop get the most performance from its small-diameter tools.

-

Turning The Tide

When Briggs & Stratton decided to make the crankshaft machining lines in its Poplar Bluff plant globally competitive, it had to choose between CNC lathes and dedicated special machines for its main turning operations. The company chose the lathes.

-

Mainstream Technology Keeps Shop On Track

In its toolroom, Branchline Trains takes a practical approach to machining with end mills as small as 0.005 inch in diameter.

-

Machining Composites By Conventional Means

Composites machining is dusty, messy and hard on tools. But this company accepts these difficulties, and machines the material using standard metalworking processes and equipment.

-

Just Enough Automation

Automated gantry loaders helped this shop make the transition from job shop to product line manufacturer.

-

Sourcing Automation

A new kind of 'automation project manager' helped this company install a roboticized machining cell, the first of several now operating in its plant.

-

CNC Robotics And Automation: Knowing When To Say 'When'

In metalworking, a shop's move from one level of automation to the next can be a business-busting decision if badly timed. This article looks at what you should consider when taking the next step toward automating an operation.

-

High Speed Machining: Aerospace -- Boeing's One Part Harmony

Faster, lighter cuts can let one solid part replace an assembly of hundreds of components. Better manufacturing and a better airplane both result. But before Boeing could realize these benefits, a more finely tuned process was needed.

-

Sizing Up The Future

This shop installed a bigger CMM to meet its current needs, but the software that came with it has the shop ready for what lies ahead.

-

Consider Closing The Loop

Looking for a way to reduce process variability, speed setup, simplify your operation? Automatic measurement and machine compensation (Closed Loop Machining) may be something to consider. Here's a shop where it's making a difference.

-

No Experience Necessary

This shop assembled standard machine tools and components into a process for flexible production of a series of complex hydraulic cylinder components - all machined from solid, all accurate in some dimensions to +/-0.025 mm - in quantities that can exceed 3,000 per day, using only two operators per shift to shepherd this production from bar stock to shipping container.

-

Low Cost Turning Automation Yields A High Rate Of Return

Two CNC lathes, with live tooling, tool monitor, and auto-load short-bar bar feeders are helping this California manufacturer compete. They've seen impressive reductions in throughput time and manufacturing costs. And, they're just getting started.